by Mud@r_M1 | Nov 25, 2023 | Information

Overview

What are slotting metalworking machines?

Slotting metalworking machines are versatile tools used in the manufacturing industry. They are designed to create slots, grooves, and keyways on various materials such as metal, plastic, and wood. These machines consist of several key components that work together to ensure precise and accurate slotting operations. The main components include the base, column, ram, and tool head. The base provides a stable foundation for the machine, while the column supports the ram and tool head. The ram moves vertically to perform the slotting action, while the tool head holds the cutting tool. Slotting metalworking machines are commonly used in industries such as automotive, aerospace, and construction. They play a crucial role in producing parts with intricate slots and keyways, ensuring the proper functioning of various mechanical systems.

Importance of slotting metalworking machines

Slotting metalworking machines are a crucial component in the manufacturing industry. These machines play a vital role in shaping and cutting materials to create precise slots and grooves. They are commonly used in various industries such as automotive, aerospace, and construction. The importance of slotting metalworking machines cannot be overstated as they enable manufacturers to produce intricate and complex components with high precision. These machines offer versatility, allowing for the creation of slots of different sizes and depths. They are also known for their durability and efficiency, ensuring smooth and accurate operations. With the advancements in technology, slotting metalworking machines have become more advanced and sophisticated, incorporating features like computer numerical control (CNC) systems for enhanced precision and automation. Overall, slotting metalworking machines are indispensable tools that significantly contribute to the efficiency and quality of manufacturing processes.

Applications of slotting metalworking machines

Slotting metalworking machines are versatile tools that find applications in various industries. These machines are commonly used for shaping and cutting materials such as metal, wood, and plastic. They are particularly useful in the manufacturing sector for creating slots, keyways, and grooves on workpieces. Slotting machines are also employed in the automotive industry for producing gears, sprockets, and pulleys. Additionally, these machines are utilized in the construction industry for fabricating components like brackets and supports. With their ability to perform precise and intricate operations, slotting metalworking machines are essential for achieving accurate and high-quality results in a wide range of applications.

Key Components of Slotting Metalworking Machines

Ram and Ram Head

The ram and ram head are key components of slotting metalworking machines. The ram is a vertical component that moves up and down, while the ram head is the part of the ram that holds the cutting tool. These components play a crucial role in the operation of the machine, as they determine the depth and accuracy of the cuts. The ram and ram head are typically made of high-quality materials to ensure durability and precision. Proper maintenance and lubrication of these components are essential to prolong their lifespan and maintain optimal performance. With their robust design and precise functionality, the ram and ram head are indispensable in slotting metalworking machines.

Tool Head and Tool Slide

The tool head and tool slide are key components of slotting metalworking machines. The tool head is responsible for holding and controlling the cutting tool, while the tool slide provides the necessary movement and positioning. These components work together to ensure precise and efficient metalworking operations. The tool head is typically equipped with various tools, such as cutting blades or shaping tools, which can be easily interchanged depending on the desired operation. The tool slide, on the other hand, allows for vertical movement and adjustment of the tool head, enabling the machine to perform different cutting depths and shapes. The tool head and tool slide are crucial for achieving accurate and high-quality slotting results. It is important to properly maintain and calibrate these components to ensure optimal performance and extend the lifespan of the machine.

Feed Mechanism

The feed mechanism is a crucial component in slotting metalworking machines. It is responsible for controlling the movement of the workpiece during the machining process. This mechanism ensures precise and consistent feeding of the workpiece, resulting in accurate and high-quality slotting operations. The feed mechanism typically consists of a feed screw, feed nut, and feed handle. The feed screw is driven by a motor, which rotates the screw and moves the workpiece forward or backward. The feed nut is attached to the worktable and engages with the feed screw, translating the rotational motion into linear movement. The feed handle allows the operator to control the speed and direction of the feed. Proper maintenance and adjustment of the feed mechanism are essential to ensure optimal performance and extend the lifespan of the machine. Bold keywords: feed mechanism, workpiece, machining process, precise, consistent feeding, accurate, high-quality slotting operations, feed screw, feed nut, feed handle, motor, worktable, rotational motion, linear movement, speed, direction, maintenance, adjustment, optimal performance, lifespan, machine.

Design Considerations for Slotting Metalworking Machines

Machine Structure

The machine structure is a critical aspect of slotting metalworking machines. It refers to the overall design and construction of the machine, including its frame, base, and components. A well-designed machine structure ensures stability, precision, and durability during the slotting process. The frame provides a rigid support for the machine, while the base serves as a foundation for stability. The components, such as the ram, table, and tooling, are carefully engineered to perform specific functions. By optimizing the machine structure, manufacturers can enhance the performance and efficiency of slotting metalworking machines.

Control System

The control system is a crucial component of slotting metalworking machines. It is responsible for managing and coordinating the various operations of the machine, ensuring precise and accurate results. With an advanced control system, operators can easily program the machine to perform complex tasks, such as creating intricate slots and shapes. The control system also allows for real-time monitoring and adjustment of parameters, ensuring optimal performance and efficiency. Overall, a robust control system is essential for maximizing the productivity and functionality of slotting metalworking machines.

Safety Features

Slotting metalworking machines are essential tools in the manufacturing industry. They are used for cutting and shaping metal materials to create various products. These machines consist of several key components that work together to ensure smooth and efficient operation. The design of slotting metalworking machines incorporates various safety features to protect operators and minimize the risk of accidents. These safety features include emergency stop buttons, safety guards, and interlocking mechanisms. By implementing these safety measures, operators can work with confidence and peace of mind, knowing that their well-being is prioritized. It is important to familiarize oneself with these safety features and follow proper operating procedures to ensure a safe working environment.

Advantages of Slotting Metalworking Machines

High Precision Machining

High precision machining is a crucial aspect of slotting metalworking machines. It involves the use of advanced techniques and cutting-edge technology to achieve precise and accurate results. This process requires careful attention to detail and a deep understanding of the materials and tools involved. With high precision machining, manufacturers can create intricate designs and achieve tight tolerances, ensuring the highest quality output. Whether it’s for creating complex parts or achieving smooth surface finishes, high precision machining plays a vital role in the success of slotting metalworking machines.

Versatility in Operations

Versatility in operations is one of the key components that sets slotting metalworking machines apart. These machines are designed to handle a wide range of tasks, making them highly adaptable to different manufacturing needs. Whether it’s cutting, shaping, or slotting, these machines can do it all. With their advanced features and precision engineering, slotting metalworking machines offer unparalleled flexibility and efficiency. They are the go-to choice for industries that require versatile and reliable equipment. From automotive to aerospace, these machines have proven their worth in various sectors. So, if you’re looking for a machine that can handle multiple operations with ease, look no further than slotting metalworking machines.

Cost-effectiveness

Slotting metalworking machines are an essential component of any manufacturing process. They are designed to create slots, grooves, and keyways in metal workpieces, allowing for precise and accurate machining. These machines are known for their cost-effectiveness, as they can perform multiple operations in a single setup, reducing the need for additional equipment and labor. By utilizing slotting metalworking machines, manufacturers can increase productivity, improve efficiency, and ultimately save on production costs. With their robust construction and advanced features, these machines offer a reliable and durable solution for slotting metal workpieces. Whether used in small-scale workshops or large-scale production facilities, slotting metalworking machines are an indispensable tool for achieving high-quality results.

Common Applications of Slotting Metalworking Machines

Keyway Cutting

Keyway cutting is a crucial process in metalworking machines that involves creating slots or keyways in a workpiece. These keyways are used to secure components such as gears, pulleys, and shafts, ensuring proper alignment and transmission of power. The key components of a slotting metalworking machine for keyway cutting include a cutting tool, a workpiece holder, and a feed mechanism. The cutting tool, often a broach or a slotting cutter, is responsible for removing material and creating the keyway. The workpiece holder securely holds the workpiece in place during the cutting process, preventing any movement or misalignment. The feed mechanism controls the movement of the cutting tool, allowing precise and controlled cutting. Keyway cutting is a fundamental operation that requires careful planning, accurate measurements, and skilled operators. By understanding the key components and design of slotting metalworking machines, manufacturers can ensure the efficient and accurate production of keyways in their workpieces.

Internal and External Shaping

Slotting metalworking machines are essential tools in the manufacturing industry. They are used for shaping and cutting various materials, such as metal, to create precise and intricate designs. These machines consist of several key components that work together to ensure efficient and accurate operations. The design of slotting metalworking machines is carefully engineered to provide stability, durability, and ease of use. Internal and external shaping is a crucial aspect of these machines, as it allows for the creation of different shapes and contours. This process involves the use of specialized tools and techniques to shape the material according to specific requirements. The internal shaping focuses on creating holes and recesses within the material, while the external shaping involves forming the outer surface. The combination of these shaping techniques enables manufacturers to produce a wide range of products with varying shapes and sizes. Overall, slotting metalworking machines play a vital role in the manufacturing process and contribute to the production of high-quality and precise components.

Broaching

Broaching is a machining process that uses a toothed tool, called a broach, to remove material from a workpiece. It is commonly used for producing keyways, splines, and other internal or external profiles. The broach is pushed or pulled through the workpiece, cutting the desired shape. This process is known for its accuracy and efficiency, making it a popular choice in the metalworking industry. Broaching machines are designed to handle various materials and can be customized to meet specific requirements. With their ability to create precise and complex shapes, broaching machines play a crucial role in the manufacturing of metal components.

Conclusion

Importance of slotting metalworking machines in modern manufacturing

Slotting metalworking machines are an indispensable tool in modern manufacturing. They play a crucial role in creating precise slots and grooves in metal workpieces, allowing for the assembly of complex machinery and components. With their ability to accurately cut and shape metal, slotting machines ensure the proper fit and function of various parts, enhancing the overall quality and performance of the final product. These machines are widely used in industries such as automotive, aerospace, and electronics, where precision and efficiency are paramount. By utilizing slotting metalworking machines, manufacturers can streamline their production processes, reduce manual labor, and achieve higher levels of productivity. The importance of these machines in modern manufacturing cannot be overstated, as they enable the creation of intricate and intricate designs that would be otherwise challenging or impossible to achieve. Bold keywords: slotting metalworking machines, modern manufacturing, precise slots and grooves, complex machinery and components, accurate cut and shape metal, enhance overall quality and performance, automotive, aerospace, electronics, precision and efficiency, streamline production processes, reduce manual labor, achieve higher levels of productivity, intricate designs.

Continuous advancements in slotting machine technology

Continuous advancements in slotting machine technology have revolutionized the metalworking industry. These machines, equipped with state-of-the-art features and cutting-edge designs, have significantly improved the efficiency and precision of slotting operations. With the integration of advanced automation systems, slotting machines now offer enhanced control and versatility, allowing operators to achieve complex slotting patterns with ease. The use of high-quality materials and innovative engineering techniques has resulted in machines that are not only durable but also capable of delivering exceptional performance. From the development of more compact and space-saving designs to the incorporation of advanced safety features, slotting machines have undergone remarkable transformations. As a result, manufacturers and metalworkers can now rely on these machines to meet their slotting needs with utmost confidence and efficiency.

Future prospects of slotting metalworking machines

Slotting metalworking machines have come a long way in terms of design and functionality. With advancements in technology, these machines are now capable of performing intricate operations with precision and accuracy. The future prospects of slotting metalworking machines look promising, as they continue to evolve and adapt to the changing needs of the industry. One key component that contributes to their success is the use of innovative materials and cutting-edge techniques. These machines are built to withstand heavy-duty usage and provide efficient performance. Another important aspect is the integration of automation and computer numerical control (CNC) systems, which enhance productivity and reduce human error. The combination of these factors ensures that slotting metalworking machines will remain an essential tool in various industries, including automotive, aerospace, and manufacturing. As technology continues to advance, we can expect even more exciting developments in the field of slotting metalworking machines.

by Mud@r_M1 | Nov 25, 2023 | Information

Overview

What are slotting metalworking machines?

Slotting metalworking machines are versatile tools used in various industries. These machines are designed to create slots, grooves, and keyways in a wide range of materials, including metal, plastic, and wood. They are commonly used in manufacturing processes, such as shaping and finishing components for machinery and equipment. Slotting metalworking machines feature a vertical cutting tool known as a slotting tool or ram. This tool moves up and down to cut precise slots into the workpiece. With their ability to create intricate and precise slots, these machines play a crucial role in the production of gears, pulleys, and other components. Whether it’s in the automotive, aerospace, or construction industry, slotting metalworking machines are essential for achieving high-quality and accurate results.

How do slotting metalworking machines work?

Slotting metalworking machines are versatile tools that are used in various industries for a wide range of applications. These machines work by using a reciprocating motion to create slots, grooves, and other intricate shapes on metal surfaces. The main components of a slotting machine include a ram, a cutting tool, and a worktable. The ram moves up and down, while the cutting tool removes material from the workpiece to create the desired shape. Slotting metalworking machines are commonly used in industries such as automotive, aerospace, and manufacturing. They are especially useful for creating keyways, splines, and internal and external gears. With their precise cutting capabilities, slotting metalworking machines play a crucial role in the production of high-quality metal components.

Importance of slotting metalworking machines

Slotting metalworking machines play a crucial role in various industries. These machines are used to create slots, grooves, and keyways in metal components. They are essential for tasks such as shaping, cutting, and finishing metal parts. The importance of slotting metalworking machines cannot be overstated, as they enable precise and efficient machining operations. With their ability to handle different materials and produce accurate results, these machines are indispensable in industries such as automotive, aerospace, and manufacturing. Whether it’s creating intricate designs or improving the functionality of metal components, slotting metalworking machines are a valuable asset in the production process.

Applications in the Automotive Industry

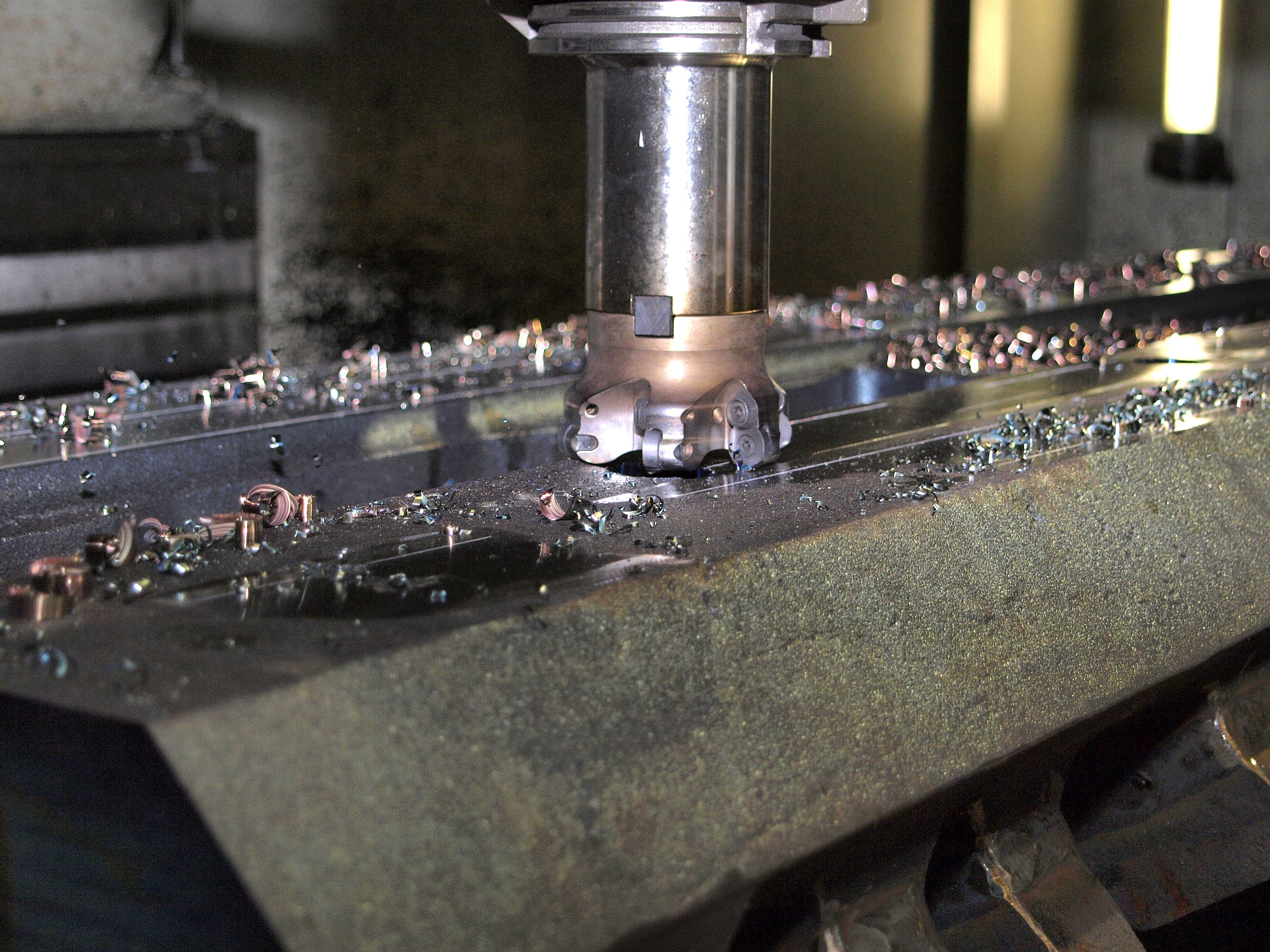

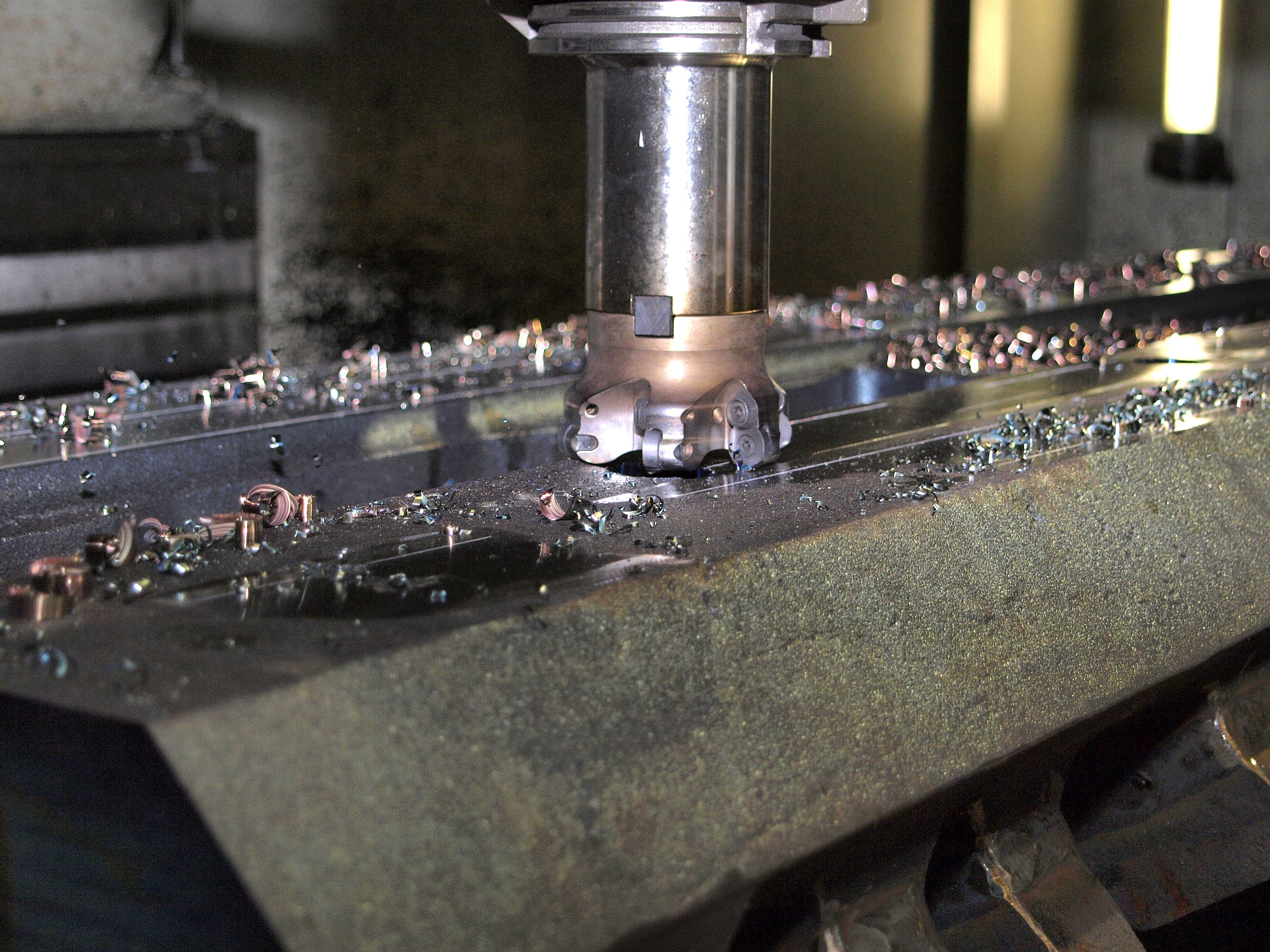

Slotting machines for engine block manufacturing

Slotting machines are versatile tools used in various industries for a wide range of applications. One of the key areas where slotting machines are extensively used is in engine block manufacturing. These machines play a crucial role in shaping and cutting slots in engine blocks, ensuring precise and accurate results. With their robust construction and advanced features, slotting machines offer high efficiency and productivity in the manufacturing process. They are capable of handling different materials and can be customized to meet specific requirements. Additionally, slotting machines are equipped with safety features to ensure the well-being of operators. Overall, slotting machines are indispensable in engine block manufacturing, providing the necessary precision and reliability for the production of high-quality engine blocks.

Slotting machines for gear manufacturing

Slotting machines are a crucial tool in the gear manufacturing industry. These machines are specifically designed to create slots in gears, allowing for smooth and precise movement. With their precise cutting capabilities, slotting machines ensure that gears are accurately shaped and aligned, resulting in high-quality products. The use of slotting machines in gear manufacturing has revolutionized the industry, making the production process more efficient and reliable. Whether it’s for large-scale industrial gear production or small-scale custom gear manufacturing, slotting machines play a vital role in ensuring the functionality and durability of gears. Their versatility and precision make them an indispensable tool in various industries, including automotive, aerospace, and machinery manufacturing. By investing in slotting machines, companies can enhance their gear manufacturing capabilities and deliver superior products to their customers.

Slotting machines for brake system components

Slotting machines are versatile tools that are widely used in various industries for shaping and cutting metal components. One specific application of slotting machines is in the manufacturing of brake system components. These machines play a crucial role in creating precise slots and grooves in brake discs, pads, and calipers, ensuring optimal performance and safety. The use of slotting machines in the brake system industry allows for efficient production processes and consistent quality. With their ability to handle different materials and produce intricate designs, slotting machines have become an indispensable tool in the production of brake system components.

Applications in the Aerospace Industry

Slotting machines for aircraft engine components

Slotting machines are versatile tools that are widely used in various industries. One such industry that greatly benefits from the use of slotting machines is the aircraft engine component manufacturing industry. These machines play a crucial role in the production of precision components for aircraft engines. They are used to create slots, keyways, and other intricate shapes in engine components, ensuring a perfect fit and optimal performance. Slotting machines in this industry are equipped with advanced features and technologies to meet the high demands of aviation standards. They are capable of handling a wide range of materials, including metals like aluminum, titanium, and stainless steel. With their precise cutting capabilities, slotting machines contribute to the production of reliable and efficient aircraft engine components. Bold keywords: slotting machines, aircraft engine component manufacturing industry, precision components, slots, keyways, intricate shapes, perfect fit, optimal performance, advanced features, aviation standards, materials, aluminum, titanium, stainless steel, precise cutting capabilities, reliable, efficient.

Slotting machines for aircraft structural parts

Slotting machines are versatile tools that can be used in various industries. One such industry that greatly benefits from slotting machines is the aircraft industry, specifically in the production of structural parts. Slotting machines play a crucial role in the manufacturing process of aircraft structural parts, as they are capable of creating precise slots and grooves in metal components. These machines ensure the accuracy and quality of the parts, contributing to the overall safety and performance of the aircraft. With their ability to handle different materials and produce intricate designs, slotting machines have become a vital tool for the aircraft industry. Their efficiency and reliability make them an essential asset in the production of aircraft structural parts.

Slotting machines for landing gear manufacturing

Slotting machines are an essential tool in the manufacturing process of landing gear. These machines are specifically designed to create precise slots in metal components, ensuring a secure and reliable connection. With their advanced features and capabilities, slotting machines offer a high level of accuracy and efficiency, making them ideal for the production of landing gear in various industries. Whether it’s for aerospace, automotive, or heavy machinery applications, slotting machines play a crucial role in ensuring the quality and performance of landing gear.

Applications in the Electronics Industry

Slotting machines for PCB manufacturing

Slotting machines are an essential tool in the PCB manufacturing industry. These machines are used to create slots and grooves in printed circuit boards, allowing for the insertion of various components. With their precision and efficiency, slotting machines ensure that the PCBs are accurately and securely assembled. The use of slotting machines in PCB manufacturing has revolutionized the industry, making it easier and faster to produce high-quality circuit boards. From small-scale electronics to large-scale industrial applications, slotting machines have become indispensable in various industries.

Slotting machines for electronic enclosure fabrication

Slotting machines are essential tools in the electronic enclosure fabrication industry. These machines are used to create precise slots and grooves in metal sheets, which are then used to assemble electronic enclosures. The slotting process is crucial for ensuring the proper fit and alignment of components within the enclosure, as well as for improving the overall structural integrity of the product. With the use of advanced slotting machines, manufacturers can achieve high levels of accuracy and efficiency in their fabrication processes. Some of the key industries that benefit from the application of slotting machines include electronics manufacturing, telecommunications, automotive, and aerospace. By incorporating slotting machines into their production workflows, companies can streamline their manufacturing processes and deliver high-quality enclosures to their customers.

Slotting machines for connector production

Slotting machines are versatile tools that play a crucial role in various industries. One such industry where slotting machines find extensive use is connector production. These machines are specifically designed to create slots and grooves in metal components, allowing for the precise fitting of connectors. With their high precision and accuracy, slotting machines ensure that connectors are securely held in place, providing reliable electrical connections. The use of slotting machines in connector production not only enhances the efficiency of the manufacturing process but also contributes to the overall quality and durability of the connectors produced. Whether it’s for automotive, aerospace, or electronic applications, slotting machines are indispensable in connector production.

Applications in the Furniture Industry

Slotting machines for wooden furniture production

Slotting machines are versatile tools used in various industries for different purposes. One such industry where slotting machines are widely used is the wooden furniture production industry. These machines play a crucial role in shaping and creating intricate designs on wooden furniture pieces. They are capable of cutting slots, grooves, and keyways with precision and accuracy. With the ability to handle different types of wood and produce consistent results, slotting machines have become an essential tool for furniture manufacturers. The use of slotting machines in wooden furniture production not only increases productivity but also allows for the creation of unique and visually appealing designs. Whether it’s creating decorative patterns or ensuring proper fitting of joints, slotting machines are indispensable in the furniture manufacturing process.

Slotting machines for metal furniture manufacturing

Slotting machines are an essential tool in the metal furniture manufacturing industry. These machines are used to create precise and intricate slots in metal components, allowing for easy assembly and durability. With their ability to cut through various metals, slotting machines offer versatility in the production of furniture pieces such as chairs, tables, and cabinets. The use of slotting machines ensures that metal furniture is of high quality and meets industry standards. By incorporating advanced technology and innovative features, these machines enable manufacturers to produce furniture that is not only functional but also aesthetically pleasing. Whether it’s creating slots for joints or decorative patterns, slotting machines play a crucial role in the production process, making them an indispensable tool for metal furniture manufacturers.

Slotting machines for upholstery fabrication

Slotting machines are versatile tools used in various industries for upholstery fabrication. These machines are designed to create precise slots and grooves in materials such as wood, metal, and plastic. With their adjustable speed and cutting depth, slotting machines offer flexibility and accuracy in creating intricate designs and patterns. They are commonly used in the furniture industry for creating decorative details on upholstery pieces, such as chair legs and armrests. Additionally, slotting machines find applications in the automotive and aerospace industries for fabricating components with precise slots for assembly purposes. The use of slotting machines in these industries ensures efficient production processes and high-quality end products. Overall, slotting machines play a crucial role in upholstery fabrication by enabling the creation of intricate designs and patterns with precision and efficiency.

Conclusion

Advantages of using slotting metalworking machines

Slotting metalworking machines offer several advantages in various industries. These machines are highly versatile and can be used for a wide range of applications. One of the key advantages is their ability to create precise and intricate slots in metal components. This is especially useful in industries such as automotive, aerospace, and manufacturing, where precision is crucial. Slotting machines also offer high efficiency and productivity, allowing for faster production rates. Additionally, these machines can handle different types of materials, including steel, aluminum, and brass. This versatility makes slotting metalworking machines a valuable asset in any industry that requires precise slotting operations.

Future trends in slotting metalworking machines

Slotting metalworking machines have been a crucial part of various industries for many years. Their ability to accurately shape and cut materials has made them indispensable in the manufacturing sector. However, as technology continues to advance, so do slotting metalworking machines. In the future, we can expect to see several exciting trends in this field. One such trend is the integration of artificial intelligence (AI) and machine learning algorithms into slotting machines. This will enable them to analyze and adapt to different materials and cutting techniques, resulting in even more precise and efficient operations. Another trend is the development of compact and portable slotting machines, allowing for greater flexibility and ease of use. Additionally, there is a growing focus on sustainability, with manufacturers incorporating eco-friendly features into slotting machines, such as energy-efficient motors and recyclable materials. These future trends in slotting metalworking machines promise to revolutionize the industry and pave the way for exciting advancements and possibilities.

Final thoughts on the versatility of slotting metalworking machines

Slotting metalworking machines are incredibly versatile and can be used in a wide range of industries. Whether it’s in automotive manufacturing, aerospace engineering, or even the production of household appliances, these machines play a crucial role in shaping and forming various metal components. With their precise cutting and shaping capabilities, slotting metalworking machines offer unparalleled flexibility and efficiency. They can create intricate designs and patterns, ensuring that the final products meet the highest standards of quality and precision. Moreover, these machines are designed to handle different types of materials, including steel, aluminum, and brass, making them suitable for a diverse range of applications. In conclusion, the versatility of slotting metalworking machines makes them indispensable tools in many industries, enabling manufacturers to achieve exceptional results in their production processes.

by Mud@r_M1 | Nov 25, 2023 | Information

Overview

What are slotting metalworking machines?

Slotting metalworking machines are versatile tools used in the metalworking industry. They are specifically designed to create slots or grooves in various materials, including metal. These machines are commonly used in manufacturing processes such as shaping, cutting, and finishing. Slotting machines consist of a vertical ram and a cutting tool that moves up and down to create precise slots. The cutting tool can be adjusted to different depths and widths, allowing for customization and flexibility. With their robust construction and precise cutting capabilities, slotting metalworking machines are essential equipment for any metalworking workshop.

How do slotting metalworking machines work?

Slotting metalworking machines are a fascinating piece of equipment that play a crucial role in shaping metal components. These machines work by using a reciprocating cutting tool, known as a slotting tool, to create slots or grooves in a workpiece. The slotting tool moves up and down in a vertical motion, cutting into the metal and removing material to form the desired shape. This process is commonly used in industries such as automotive, aerospace, and manufacturing, where precision and accuracy are paramount. By understanding how slotting metalworking machines work, engineers and machinists can effectively utilize these machines to create intricate and precise metal parts.

Why are slotting metalworking machines important?

Slotting metalworking machines are an essential tool in the manufacturing industry. They play a crucial role in shaping and cutting materials, creating precise slots and grooves. These machines are important for various reasons. Firstly, they allow for the production of intricate designs and patterns that cannot be achieved by other machines. Secondly, slotting machines are highly versatile and can be used with different types of materials, such as metal, wood, and plastic. This makes them suitable for a wide range of industries, including automotive, aerospace, and furniture manufacturing. Additionally, slotting machines are known for their accuracy and precision, ensuring that the final product meets the required specifications. Lastly, these machines are designed to improve efficiency and productivity, allowing manufacturers to meet tight deadlines and deliver high-quality products. Overall, slotting metalworking machines are indispensable tools that contribute to the success of the manufacturing industry.

Types of slotting metalworking machines

Horizontal slotting machines

Horizontal slotting machines are a type of metalworking machine that is used to create slots or grooves in a workpiece. These machines are characterized by their horizontal orientation, which allows for easy access and maneuverability. They are commonly used in industries such as automotive, aerospace, and manufacturing. With their powerful cutting capabilities and precise control, horizontal slotting machines are essential tools for shaping and machining metal. Whether you are a professional machinist or a hobbyist, understanding the operation and applications of horizontal slotting machines can greatly enhance your metalworking skills.

Vertical slotting machines

Vertical slotting machines are versatile tools used in metalworking. They are designed to create slots, grooves, and keyways in various materials such as metal and plastic. These machines operate by moving a cutting tool vertically to remove material and create the desired slot. Vertical slotting machines are commonly used in industries such as automotive, aerospace, and manufacturing. They offer precise and efficient slotting capabilities, making them essential equipment for many metalworking applications. With their ability to handle different materials and produce accurate results, vertical slotting machines are a valuable asset in the metalworking industry.

Universal slotting machines

Universal slotting machines are versatile and efficient tools used in metalworking. They are designed to create slots, grooves, and keyways in various materials, such as metal and plastic. These machines offer precise and accurate cutting capabilities, making them ideal for applications that require high precision. With their adjustable stroke length and speed, universal slotting machines can accommodate different workpiece sizes and cutting requirements. They are commonly used in industries such as automotive, aerospace, and manufacturing. Whether you need to create slots for gears, keyways for shafts, or grooves for components, a universal slotting machine can provide the necessary precision and efficiency. Invest in a reliable and robust universal slotting machine to enhance your metalworking capabilities.

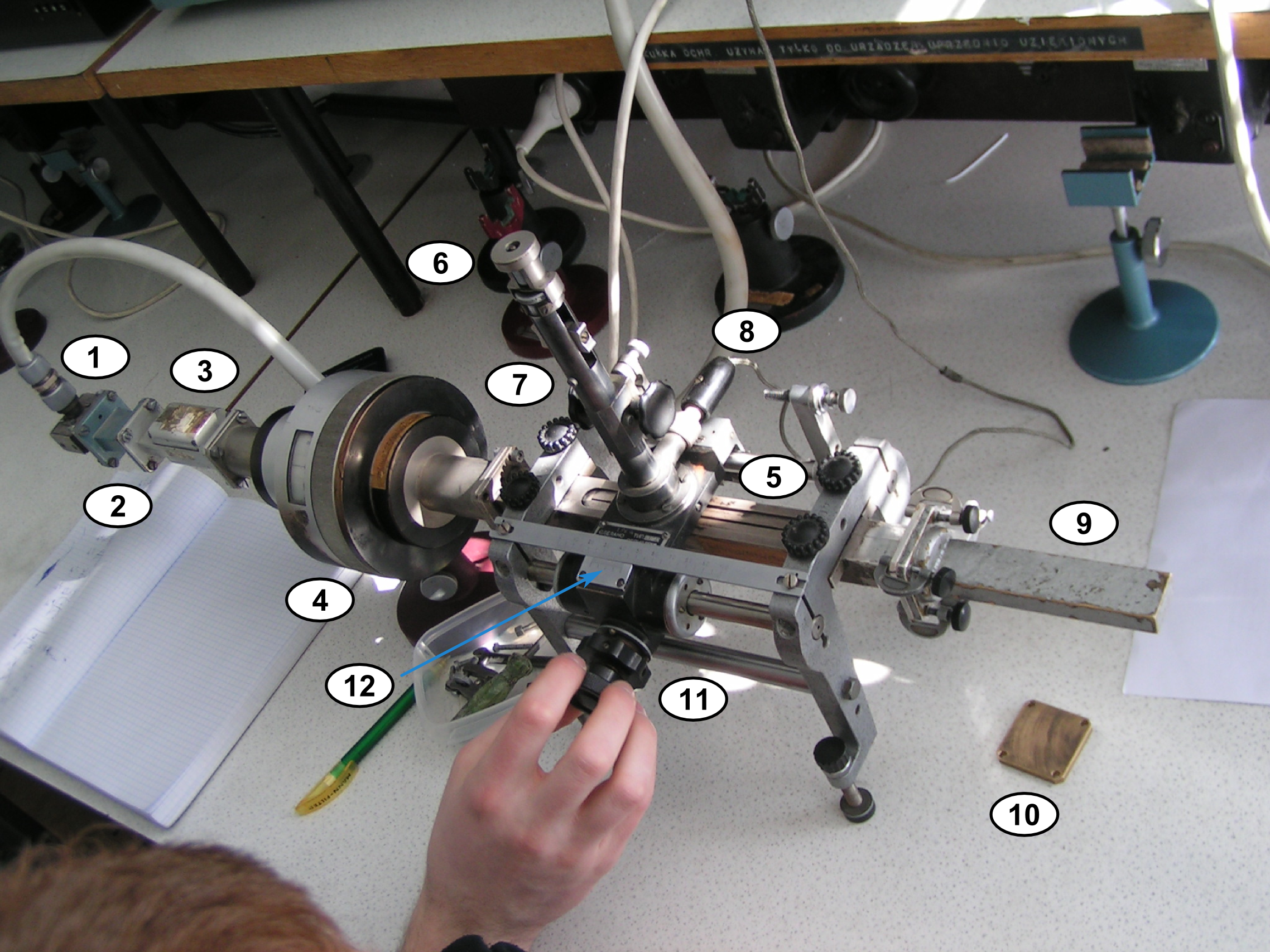

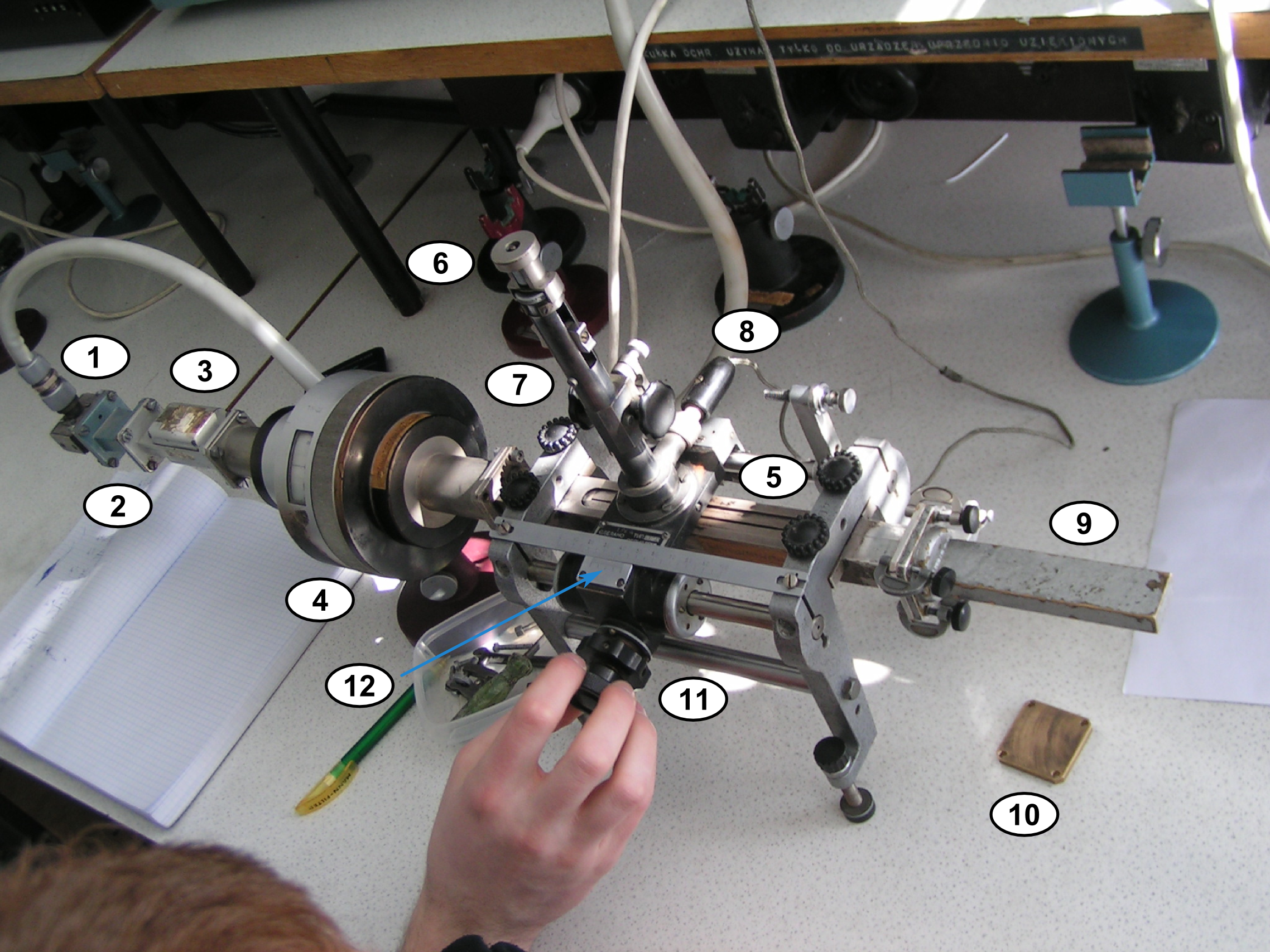

Key components of slotting metalworking machines

Ram

The ram is a crucial component of slotting metalworking machines. It is responsible for the vertical movement of the cutting tool, allowing it to create slots in the workpiece. The ram is typically powered by a hydraulic or mechanical system, providing the necessary force to drive the tool into the material. This movement is controlled by the operator, who can adjust the speed and depth of the ram to achieve the desired slotting results. The ram plays a vital role in the overall performance and precision of the machine, making it an essential part of any metalworking operation.

Tool head

The tool head is a crucial component of slotting metalworking machines. It is responsible for holding and manipulating the cutting tools during the machining process. The tool head is typically mounted on a vertical or horizontal slide, allowing for precise positioning and movement. It is designed to accommodate various types of cutting tools, such as slotting cutters, end mills, and drills. The tool head plays a vital role in determining the accuracy, efficiency, and versatility of the machine. Understanding the functionality and features of the tool head is essential for operators and technicians to maximize the performance of slotting metalworking machines.

Worktable

The worktable is an essential component of slotting metalworking machines. It serves as the surface where the workpiece is placed and secured during the machining process. The worktable is typically made of sturdy materials such as cast iron or steel, ensuring stability and durability. It is designed with precision and accuracy in mind, allowing for precise positioning and alignment of the workpiece. The worktable also features T-slots or clamping mechanisms to securely hold the workpiece in place. Additionally, some advanced slotting machines may have a rotary worktable that enables the machining of complex shapes and angles. Overall, the worktable is a crucial element that contributes to the efficiency and effectiveness of slotting metalworking machines.

Applications of slotting metalworking machines

Creating keyways

In the process of slotting metalworking machines, creating keyways is a crucial step. Keyways are narrow, rectangular slots that are cut into a shaft or hub to accommodate a key. This key helps to transmit torque and prevent slippage between the shaft and the mounted component. Keyways can be created using various methods such as broaching, milling, or shaping. Each method has its advantages and limitations, and the choice depends on factors such as the size and complexity of the keyway. Regardless of the method chosen, precision and accuracy are essential to ensure a proper fit between the key and the keyway. By creating keyways accurately, metalworking machines can be effectively used in a wide range of applications, including automotive, aerospace, and manufacturing industries.

Machining internal and external grooves

Machining internal and external grooves is a fundamental process in metalworking that involves cutting or shaping materials to create precise and functional grooves. Whether it’s for creating threads, keyways, or decorative patterns, slotting metalworking machines are essential tools in achieving accurate and reliable results. These machines utilize various cutting techniques, such as broaching, milling, or grinding, to remove material and form grooves with exceptional precision. The ability to machine internal and external grooves is crucial for industries such as automotive, aerospace, and manufacturing, where components with intricate designs and tight tolerances are required. By using slotting metalworking machines, manufacturers can efficiently produce high-quality grooves that meet the demanding requirements of modern engineering. So, whether you’re a professional machinist or a DIY enthusiast, understanding the principles and techniques behind machining internal and external grooves can open up a world of possibilities in metalworking.

Producing irregular shapes

Producing irregular shapes is a fascinating aspect of slotting metalworking machines. These machines have the capability to create unique and intricate designs that are not possible with other types of machines. By using specialized cutting tools and adjustable mechanisms, slotting machines can produce a wide range of irregular shapes such as curves, arcs, and polygons. This versatility allows manufacturers to meet the demands of various industries, including automotive, aerospace, and jewelry. With their precise control and high accuracy, slotting machines are essential tools for creating complex and visually appealing components. Whether it’s crafting custom jewelry or manufacturing intricate automotive parts, slotting machines offer endless possibilities for producing eye-catching irregular shapes.

Advantages of using slotting metalworking machines

High precision and accuracy

High precision and accuracy are essential qualities in slotting metalworking machines. These machines are designed to perform precise and accurate cuts, ensuring that the final product meets the required specifications. With their advanced technology and precise control systems, slotting metalworking machines can achieve tight tolerances and produce high-quality results. Whether it’s creating slots, keyways, or other intricate shapes, these machines deliver consistent and reliable performance. The combination of precision and accuracy in slotting metalworking machines makes them a valuable asset in various industries, including automotive, aerospace, and manufacturing.

Versatility in machining operations

Slotting metalworking machines are highly versatile in their machining operations. They are capable of performing a wide range of tasks, making them an essential tool in various industries. With their ability to create slots, grooves, and keyways with precision and accuracy, these machines offer unmatched flexibility and efficiency. Whether it’s shaping metal components, creating intricate designs, or enhancing the functionality of a product, slotting metalworking machines provide endless possibilities. Their versatility allows manufacturers to meet diverse machining needs and achieve exceptional results.

Cost-effective production

Slotting metalworking machines are a crucial tool in the manufacturing industry. They are used to create slots and grooves in various materials, such as metal and wood. Understanding how these machines work and their benefits can lead to cost-effective production. By utilizing slotting machines, manufacturers can efficiently produce high-quality products while minimizing waste and reducing production costs. With the ability to create precise and accurate slots, these machines ensure that the final product meets the required specifications. Additionally, the use of slotting machines allows for increased productivity and faster production times, leading to improved overall efficiency. Investing in slotting metalworking machines is a smart choice for any manufacturer looking to optimize their production process and achieve cost-effective results.

Conclusion

Slotting metalworking machines are essential tools in the manufacturing industry.

Slotting metalworking machines are versatile and crucial tools in the manufacturing industry. They are used to create slots, grooves, and keyways in various materials such as metal, plastic, and wood. These machines are known for their precision and efficiency, allowing manufacturers to produce intricate and complex parts with ease. With their adjustable cutting speeds and feed rates, slotting metalworking machines offer flexibility and control in the machining process. Whether it’s for shaping components or creating internal features, these machines play a vital role in the production of a wide range of products, from automotive parts to consumer electronics. The use of slotting metalworking machines not only improves productivity but also ensures the accuracy and quality of the final products. With their ability to handle different materials and produce precise cuts, these machines are indispensable in the manufacturing industry.

Understanding their types, components, applications, and advantages can help improve productivity and efficiency.

Slotting metalworking machines are a crucial part of many industries, as they play a vital role in shaping and cutting materials. Understanding their types, components, applications, and advantages can help improve productivity and efficiency. By familiarizing yourself with the different types of slotting machines available, such as horizontal and vertical slotting machines, you can choose the one that best suits your specific needs. Additionally, knowing the various components of these machines, such as the ram, table, and cutting tool, allows you to operate them effectively and troubleshoot any issues that may arise. The applications of slotting machines are diverse, ranging from creating keyways in gears to producing slots in metal workpieces. By utilizing these machines, you can achieve precise and accurate results in your manufacturing processes. Moreover, slotting machines offer several advantages, including the ability to perform intricate and complex operations, high precision, and increased productivity. By understanding the types, components, applications, and advantages of slotting metalworking machines, you can enhance your knowledge and skills in the field, ultimately improving your overall productivity and efficiency.

By utilizing slotting metalworking machines, manufacturers can achieve precise and cost-effective production.

Slotting metalworking machines are essential tools for manufacturers looking to achieve precise and cost-effective production. By utilizing these machines, manufacturers can create intricate slots and grooves in metal materials with ease. The advanced technology and precision engineering of slotting machines ensure that the final products meet the highest quality standards. Additionally, these machines offer a cost-effective solution for manufacturers, as they allow for efficient and accurate production processes. With the ability to handle various metal materials and sizes, slotting metalworking machines provide manufacturers with the flexibility to meet diverse production needs. Whether it’s creating keyways, splines, or internal and external slots, these machines offer the versatility and reliability required for successful metalworking operations.

by Mud@r_M1 | Nov 25, 2023 | Information

Overview

Introduction to Metalworking

Metalworking is a fascinating craft that has a rich history dating back thousands of years. From the ancient civilizations of Egypt and Mesopotamia to the modern industrial age, metalworking has played a crucial role in shaping our world. In this article, we will explore the fascinating history of metalworking, from its humble beginnings to its current state as a sophisticated and versatile art form. So grab your hammer and chisel, and let’s dive into the world of metalworking!

Importance of Metalworking in Human History

Metalworking has played a crucial role in shaping human history. From the earliest civilizations to the modern era, the importance of metalworking cannot be overstated. The ability to manipulate and shape metal has allowed humans to create tools, weapons, and structures that have revolutionized society. Metalworking has enabled advancements in agriculture, transportation, and warfare, leading to the development of civilizations and the rise of empires. Without metalworking, the world as we know it would be vastly different. It is truly remarkable how something as simple as heating and shaping metal can have such a profound impact on the course of human history.

Evolution of Metalworking Techniques

Metalworking has a rich and fascinating history that spans thousands of years. The evolution of metalworking techniques has been a key factor in shaping the world as we know it today. From the early days of simple hand tools to the advanced machinery and technology used in modern metalworking, the process has undergone significant changes and improvements. Throughout history, metalworkers have developed innovative techniques to shape and manipulate various metals. These techniques include casting, forging, welding, and soldering, among others. Each technique has its own unique characteristics and applications, contributing to the diverse range of metalwork we see today. The evolution of metalworking techniques has not only revolutionized the manufacturing industry but has also played a vital role in the development of civilization as a whole. It has allowed for the creation of intricate and durable metal objects, from weapons and tools to architectural structures and decorative pieces. Metalworking continues to evolve and adapt to new technologies and materials, ensuring its continued relevance and importance in our modern world.

Ancient Metalworking Techniques

Copper Age and the Birth of Metallurgy

During the Copper Age, which lasted from around 4500 to 3500 BCE, humans began to discover the remarkable properties of copper. This marked the birth of metallurgy, the process of extracting and working with metals. Copper, with its malleability and conductivity, became an essential material for tools, weapons, and decorative items. The discovery of copper’s potential led to further experimentation with other metals, such as bronze and iron, and paved the way for advancements in metalworking techniques.

Bronze Age and the Rise of Metalworking

During the Bronze Age, metalworking became a crucial part of human civilization. The discovery of bronze, an alloy of copper and tin, revolutionized the way people lived and interacted with their environment. With the development of metalworking techniques, ancient societies were able to create tools, weapons, and intricate ornaments that were previously unimaginable. The Bronze Age marked a significant shift in human history, as it laid the foundation for technological advancements and cultural exchange. This era witnessed the rise of skilled artisans who mastered the art of metalworking, shaping the course of civilization for centuries to come.

Iron Age and the Advancements in Metalworking

During the Iron Age, there were significant advancements in metalworking that revolutionized the way people worked with metals. The discovery and widespread use of iron allowed for the creation of stronger and more durable tools and weapons. This led to advancements in agriculture, construction, and warfare. Ironworking techniques such as smelting and forging became more refined, resulting in the production of intricate and ornamental metal objects. The Iron Age marked a pivotal period in the history of metalworking, laying the foundation for future innovations and developments.

Medieval Metalworking Guilds

Formation and Structure of Metalworking Guilds

Metalworking guilds played a crucial role in the development of metalworking throughout history. These guilds were formed by skilled craftsmen who specialized in various metalworking techniques such as blacksmithing, casting, and engraving. The formation of guilds allowed for the sharing of knowledge, skills, and resources among its members, leading to the advancement of metalworking techniques and the establishment of quality standards. The structure of these guilds was hierarchical, with master craftsmen overseeing the training of apprentices and journeymen. This system ensured the preservation and transmission of metalworking knowledge from one generation to the next. Metalworking guilds were not only important for the technical aspects of metalworking but also played a significant role in the social and economic fabric of communities. By organizing themselves into guilds, metalworkers were able to protect their interests, negotiate fair wages, and maintain a high level of craftsmanship. The establishment and success of metalworking guilds marked a turning point in the history of metalworking, shaping the industry as we know it today.

Role of Metalworking Guilds in Medieval Society

Metalworking guilds played a crucial role in medieval society. These guilds were organizations of skilled metalworkers who came together to protect their trade secrets, regulate the quality of metalwork, and ensure fair wages for their members. They also provided training and apprenticeships to aspiring metalworkers, passing down the knowledge and techniques of the craft from one generation to the next. The guilds had a significant impact on the economy and social structure of medieval society, with their members often holding positions of influence and power. The work of metalworking guilds contributed to the development of innovative metalworking techniques and the creation of intricate and beautiful metalwork pieces that adorned churches, castles, and other important structures of the time.

Innovations and Techniques Developed by Metalworking Guilds

Metalworking guilds have been at the forefront of innovation and development in the field. Over the centuries, these guilds have pioneered numerous techniques and introduced groundbreaking innovations that have shaped the art and science of metalworking. From the invention of the blast furnace to the refinement of alloy compositions, metalworking guilds have consistently pushed the boundaries of what is possible. Their dedication to craftsmanship and their commitment to excellence have made them a driving force in the advancement of metalworking. Today, their legacy lives on, as their techniques and knowledge continue to be passed down through generations of skilled artisans.

Industrial Revolution and Modern Metalworking

Impact of Industrial Revolution on Metalworking

The Industrial Revolution had a profound impact on metalworking. It revolutionized the way metals were produced, shaped, and used. With the introduction of new machinery and technologies, metalworking became faster, more efficient, and more precise. This led to the mass production of metal goods, which in turn fueled economic growth and transformed industries such as construction, transportation, and manufacturing. The Industrial Revolution also brought about significant changes in the skills and roles of metalworkers, as traditional techniques were replaced by automated processes. Overall, the Industrial Revolution marked a turning point in the history of metalworking, shaping it into the modern industry we know today.

Introduction of Machinery and Mass Production

Metalworking has a long and fascinating history, with the introduction of machinery and mass production playing a pivotal role in its development. In the early days, metalworking was a labor-intensive process, requiring skilled craftsmen to shape and manipulate metal by hand. However, with the advent of machinery and the ability to produce metal products on a larger scale, the industry underwent a significant transformation. This revolutionized the way metal was manufactured, making it more accessible and affordable for a wider range of people. The introduction of machinery and mass production not only increased efficiency and productivity but also paved the way for new innovations and advancements in metalworking techniques. Today, metalworking continues to evolve and adapt, with modern technologies and techniques pushing the boundaries of what is possible in this ancient craft.

Modern Metalworking Techniques and Applications

Metalworking has come a long way in recent years, thanks to modern techniques and applications. With advancements in technology, metalworkers now have access to a wide range of tools and equipment that make their work more efficient and precise. From computer-aided design (CAD) software to laser cutting machines, these innovations have revolutionized the metalworking industry. Today, metalworkers are able to create intricate designs and shapes with ease, pushing the boundaries of what was once thought possible. Whether it’s crafting custom jewelry or building large-scale structures, modern metalworking techniques have opened up a world of possibilities. So, if you’re looking to explore the fascinating world of metalworking, don’t hesitate to dive in and discover the endless opportunities that await you.

Metalworking in Art and Architecture

Metalworking in Ancient Sculptures and Artifacts

Metalworking has a rich history that dates back to ancient times. In fact, metalworking can be traced back to the ancient civilizations of Mesopotamia, Egypt, and Greece. These ancient societies used metal to create intricate sculptures and artifacts, showcasing their advanced skills and craftsmanship. Metalworking in ancient sculptures and artifacts played a significant role in the development of art and culture during this time period. The use of metals such as bronze and iron allowed artists to create detailed and durable pieces that have withstood the test of time. From statues of gods and goddesses to ornate jewelry and weapons, metalworking in ancient sculptures and artifacts continues to fascinate and inspire us today.

Metalworking Techniques in Gothic Architecture

Metalworking techniques in Gothic architecture played a crucial role in shaping the iconic structures of the time. From intricate ironwork to elaborate stained glass windows, these techniques showcased the mastery and creativity of medieval craftsmen. The use of bold keywords like ‘metalworking techniques‘, ‘Gothic architecture’, ‘iconic structures’, and ‘medieval craftsmen’ adds emphasis and highlights the key elements of this topic.

Contemporary Metalworking in Art Installations

Contemporary metalworking in art installations has become a captivating and innovative form of artistic expression. Artists today are pushing the boundaries of traditional metalworking techniques to create awe-inspiring installations that captivate audiences around the world. These installations often feature bold and striking designs, showcasing the versatility and beauty of metals such as steel, bronze, and aluminum. By combining traditional craftsmanship with modern technology, artists are able to create intricate and complex pieces that leave a lasting impression. Whether it’s a large-scale outdoor sculpture or a smaller, more intimate installation, contemporary metalworking in art installations continues to push the boundaries of what is possible in the world of art.

Conclusion

Significance of Metalworking in Human Civilization

Metalworking has played a significant role in shaping human civilization. From the early days of ancient civilizations to the modern industrial era, metalworking has been a driving force behind technological advancements and societal progress. The ability to manipulate and shape metal materials has allowed humans to create tools, weapons, and structures that have revolutionized various aspects of life. From the development of bronze and iron tools to the construction of towering skyscrapers, metalworking has left an indelible mark on our history. It has not only provided us with practical solutions but has also become an art form, with metalworkers showcasing their creativity and craftsmanship. The significance of metalworking cannot be overstated, as it continues to impact our daily lives in countless ways.

Continued Innovation and Advancements in Metalworking

Metalworking has come a long way since its early beginnings. From the ancient civilizations that first discovered the art of shaping metal, to the modern techniques and technologies used today, there has been a continuous drive for innovation and advancement in this field. Continued innovation in metalworking has led to the development of new materials, improved techniques, and more efficient processes. Today, metalworkers are able to create intricate and complex designs, pushing the boundaries of what was once thought possible. With the use of state-of-the-art equipment and cutting-edge technologies, metalworking has become a highly specialized and respected craft. Metalworkers are constantly pushing the limits of their creativity and skill, creating works of art that are not only functional but also visually stunning. The history of metalworking is a testament to human ingenuity and the endless possibilities that can be achieved through innovation and determination.

Appreciation for the Craftsmanship of Metalworkers

Metalworking is a fascinating craft that has captivated humans for centuries. From the intricate designs of ancient jewelry to the towering structures of modern architecture, metalworkers have showcased their incredible skill and creativity. The appreciation for the craftsmanship of metalworkers is rooted in the understanding of the meticulous techniques and attention to detail required to shape and manipulate metal. Whether it’s the delicate filigree work of a silver pendant or the precise welding of a steel beam, metalworkers demonstrate a deep understanding of their materials and a passion for their craft. Their dedication and expertise are truly awe-inspiring, making metalworking an art form that deserves our utmost admiration.

by Mud@r_M1 | Nov 25, 2023 | Information

Overview

What is slotting?

Slotting is a technique used in various industries to optimize the placement and organization of items. It involves strategically arranging products in a way that maximizes efficiency and minimizes costs. By carefully considering factors such as product popularity, size, and frequency of replenishment, businesses can create a slotting plan that ensures easy access to high-demand items and minimizes unnecessary movement. The goal of slotting is to improve overall operational efficiency and enhance customer satisfaction. With effective slotting, businesses can streamline their inventory management processes, reduce picking and replenishment time, and ultimately increase their bottom line.

Importance of effective slotting

Effective slotting is crucial for optimizing warehouse operations and maximizing productivity. By strategically organizing inventory and assigning appropriate storage locations, businesses can minimize picking and replenishment times, reduce errors, and improve overall operational efficiency. Proper slotting also enables better space utilization, allowing for more efficient use of warehouse capacity. Additionally, effective slotting helps to enhance order accuracy and customer satisfaction, as items are more easily located and picked. Overall, implementing effective slotting techniques can significantly contribute to the success and profitability of a warehouse.

Benefits of optimizing slotting

Optimizing slotting offers a range of benefits that can significantly improve warehouse efficiency. By strategically arranging items based on their demand and storage requirements, businesses can reduce picking time, minimize travel distance, and enhance overall productivity. This leads to faster order fulfillment, reduced labor costs, and improved customer satisfaction. Moreover, optimizing slotting enables better space utilization, allowing warehouses to accommodate more inventory without the need for additional storage space. With the right slotting techniques, businesses can maximize their storage capacity and minimize the risk of stockouts. By implementing an effective slotting strategy, businesses can gain a competitive edge in the market and achieve long-term success.

Understanding Slotting Strategies

Different types of slotting strategies

Different types of slotting strategies are essential for optimizing warehouse operations. By understanding the various approaches to slotting, businesses can improve efficiency and maximize storage space. One popular strategy is random slotting, where items are placed in any available location. This method is useful for fast-moving products that require frequent access. Another strategy is dedicated slotting, where specific items are assigned to predetermined locations. This approach is beneficial for products with unique storage requirements or for maintaining organized inventory. Additionally, zone slotting involves grouping similar products together in specific areas of the warehouse. This strategy can streamline order picking and reduce travel time. By implementing a combination of these slotting strategies, businesses can enhance their overall warehouse management.

Factors to consider when choosing a slotting strategy

When choosing a slotting strategy, there are several factors that need to be considered. First and foremost, it is important to understand the unique requirements of your business. This includes the size and weight of your products, as well as the frequency of order picking. Additionally, you should take into account the layout of your warehouse and the available storage space. Another crucial factor is the demand variability of your products. By analyzing historical data and forecasting future demand, you can optimize your slotting strategy to ensure that popular items are easily accessible. Lastly, it is essential to consider the cost and feasibility of implementing different slotting strategies. By carefully evaluating these factors, you can choose a slotting strategy that maximizes efficiency and productivity in your warehouse.

Examples of successful slotting strategies

Slotting is a crucial aspect of optimizing warehouse operations. It involves strategically organizing products to maximize efficiency and minimize costs. Successful slotting strategies can have a significant impact on productivity and customer satisfaction. Here are some examples of effective slotting strategies that have proven to be successful in various industries.

Slotting Techniques for Maximizing Efficiency

ABC analysis for slotting

ABC analysis for slotting is a powerful technique that helps businesses optimize their inventory management and storage strategies. By categorizing items into three groups based on their value and usage frequency, businesses can prioritize their storage and picking processes. The ‘A’ group consists of high-value and fast-moving items that require easy access and frequent replenishment. The ‘B’ group includes medium-value items that have moderate usage frequency. The ‘C’ group comprises low-value items with low usage frequency. By implementing ABC analysis for slotting, businesses can ensure efficient space utilization, reduce picking time, and improve overall warehouse productivity.

Cross-docking as a slotting technique

Cross-docking is a highly effective slotting technique that can streamline your warehouse operations. It involves unloading incoming shipments from suppliers and immediately loading them onto outbound trucks for delivery to customers, without the need for long-term storage. By eliminating the need for traditional storage and reducing handling time, cross-docking can significantly improve efficiency and reduce costs. This technique is particularly beneficial for businesses with high-volume, fast-moving products. With cross-docking, you can optimize your inventory management, minimize storage space requirements, and ensure timely order fulfillment. Implementing cross-docking as a slotting technique can revolutionize your warehouse operations and give you a competitive edge in the market.

Dynamic slotting for seasonal products

Dynamic slotting is a crucial strategy for retailers to maximize sales and optimize inventory management, especially for seasonal products. By dynamically adjusting product placement and allocation based on demand patterns and market trends, retailers can ensure that the right products are in the right place at the right time. This not only enhances customer satisfaction but also improves operational efficiency. With dynamic slotting, retailers can effectively capitalize on seasonal peaks and minimize the risk of stockouts or excess inventory. It’s a game-changing approach that empowers retailers to stay ahead of the competition and drive revenue growth.

Utilizing Technology in Slotting

Warehouse management systems for slotting

Warehouse management systems (WMS) play a crucial role in slotting. WMS software helps optimize the placement of products within a warehouse, ensuring efficient picking and replenishment processes. By analyzing various factors such as product demand, size, weight, and velocity, WMS systems determine the most suitable locations for each item. This intelligent slotting approach minimizes travel time, reduces labor costs, and maximizes storage capacity. With the ability to track inventory in real-time and generate reports, WMS systems provide valuable insights for continuous improvement. Implementing a robust WMS solution is essential for streamlining slotting operations and enhancing overall warehouse efficiency.

Automated slotting algorithms

Automated slotting algorithms are a crucial component of modern warehouse management systems. These algorithms use advanced mathematical models and optimization techniques to determine the most efficient placement of items within a warehouse. By considering factors such as item dimensions, demand patterns, and storage constraints, automated slotting algorithms can minimize travel distances, reduce picking times, and improve overall warehouse productivity. With their ability to handle large volumes of data and make real-time adjustments, these algorithms are a game-changer for businesses looking to streamline their operations and maximize efficiency.

Data analytics for optimizing slotting

Data analytics plays a crucial role in optimizing slotting. By analyzing large volumes of data, businesses can gain valuable insights into customer behavior, product demand, and inventory levels. These insights can then be used to strategically place products in the most optimal slots, maximizing efficiency and improving overall operations. With the power of data analytics, businesses can make informed decisions and stay one step ahead of the competition. So, if you want to take your slotting strategy to the next level, harness the power of data analytics and unlock the full potential of your warehouse.

Best Practices for Slotting Optimization

Regular slotting audits

Regular slotting audits are an essential part of effective warehouse management. By conducting regular audits, businesses can ensure that their inventory is organized and optimized for maximum efficiency. Audits involve analyzing the current slotting arrangements, identifying any areas for improvement, and implementing necessary changes. These audits help businesses identify and address any issues such as overstocked or underutilized slots, misplaced items, or inefficient picking paths. By regularly auditing the slotting arrangements, businesses can improve inventory accuracy, reduce picking errors, and enhance overall warehouse productivity.

Collaborative slotting with suppliers

Collaborative slotting with suppliers is a key strategy for optimizing warehouse operations. By working closely with suppliers, businesses can ensure that the right products are in the right place at the right time. This collaborative approach allows for better inventory management, reduced stockouts, and improved customer satisfaction. By leveraging the expertise and resources of suppliers, businesses can gain valuable insights into product demand, market trends, and industry best practices. Together, businesses and suppliers can develop innovative slotting strategies that maximize efficiency, minimize costs, and drive overall success.

Continuous improvement in slotting processes

Continuous improvement is a key aspect of slotting processes. By constantly analyzing and optimizing the way items are organized and stored, businesses can maximize efficiency and productivity. This involves regularly reviewing inventory data, identifying trends and patterns, and adjusting slotting strategies accordingly. With a playful and educational tone, it’s important to emphasize the importance of continuous improvement in maintaining a well-organized and streamlined warehouse. By implementing effective slotting techniques, businesses can ensure that items are easily accessible, reducing picking time and minimizing errors. With an authoritative and friendly voice, it’s crucial to highlight that continuous improvement in slotting processes is not a one-time task but an ongoing commitment to enhancing operations and staying ahead of the competition.

Conclusion

Summary of key takeaways

Effective slotting is a crucial aspect of maximizing productivity and efficiency in various industries. It involves strategically organizing and arranging items or products within a designated space, such as a warehouse or store shelves. By implementing effective slotting techniques, businesses can optimize inventory management, reduce picking and replenishment time, and improve overall operational flow. The key to successful slotting lies in understanding the unique characteristics of the items being stored, such as their size, weight, demand, and compatibility. By considering these factors, businesses can create a well-structured slotting plan that minimizes unnecessary movement and maximizes storage capacity. Some important tips and techniques for effective slotting include analyzing sales data, implementing ABC analysis, utilizing slotting software, regularly reviewing and adjusting slotting plans, and training employees on proper slotting practices. By following these key takeaways, businesses can enhance their slotting processes and achieve greater efficiency and profitability.

Final thoughts on effective slotting

In conclusion, effective slotting is crucial for optimizing warehouse operations and maximizing productivity. By following the tips and techniques mentioned in this article, businesses can ensure that their inventory is organized efficiently, reducing picking errors and improving order fulfillment. Remember to regularly review and adjust slotting strategies to accommodate changes in product demand and inventory levels. With a well-designed slotting system, businesses can streamline their operations, save time and resources, and ultimately enhance customer satisfaction.

Future trends in slotting optimization

Future trends in slotting optimization include the use of advanced algorithms to dynamically allocate inventory, the integration of artificial intelligence to predict demand patterns, and the implementation of robotics to automate the slotting process. These advancements are aimed at improving efficiency, reducing costs, and maximizing space utilization in warehouses. By leveraging these cutting-edge technologies, businesses can stay ahead of the competition and optimize their slotting strategies for maximum productivity and profitability.

by Mud@r_M1 | Nov 25, 2023 | Information

Overview

What are slotting metalworking machines?

Slotting metalworking machines are versatile tools used in the manufacturing industry. They are designed to create slots or grooves on various materials such as metal, wood, or plastic. These machines are commonly used in the production of keyways, splines, and internal and external profiles. The main components of a slotting machine include a ram, a cutting tool, and a worktable. The ram moves up and down to create the desired slot, while the cutting tool removes material from the workpiece. Slotting metalworking machines are essential for precision machining and can be found in various industries, including automotive, aerospace, and construction. With their ability to create intricate shapes and profiles, these machines play a crucial role in the manufacturing process.

Importance of slotting metalworking machines

Slotting metalworking machines play a crucial role in various industries. These machines are used to create slots, grooves, and keyways on different types of materials. They are especially important in the manufacturing and engineering sectors, where precision and accuracy are paramount. Slotting machines are versatile and can be used for a wide range of applications, including shaping and finishing metal components. With their ability to produce intricate and precise cuts, these machines are essential for creating complex parts and ensuring the quality and functionality of the final product. Whether it’s in the automotive, aerospace, or construction industry, slotting metalworking machines are indispensable tools that help bring designs to life. Their importance cannot be overstated, as they enable manufacturers to achieve precise and consistent results, saving time and resources in the process.

How do slotting metalworking machines work?