by Mud@r_M1 | Nov 25, 2023 | Information

Overview

What are boring machines?

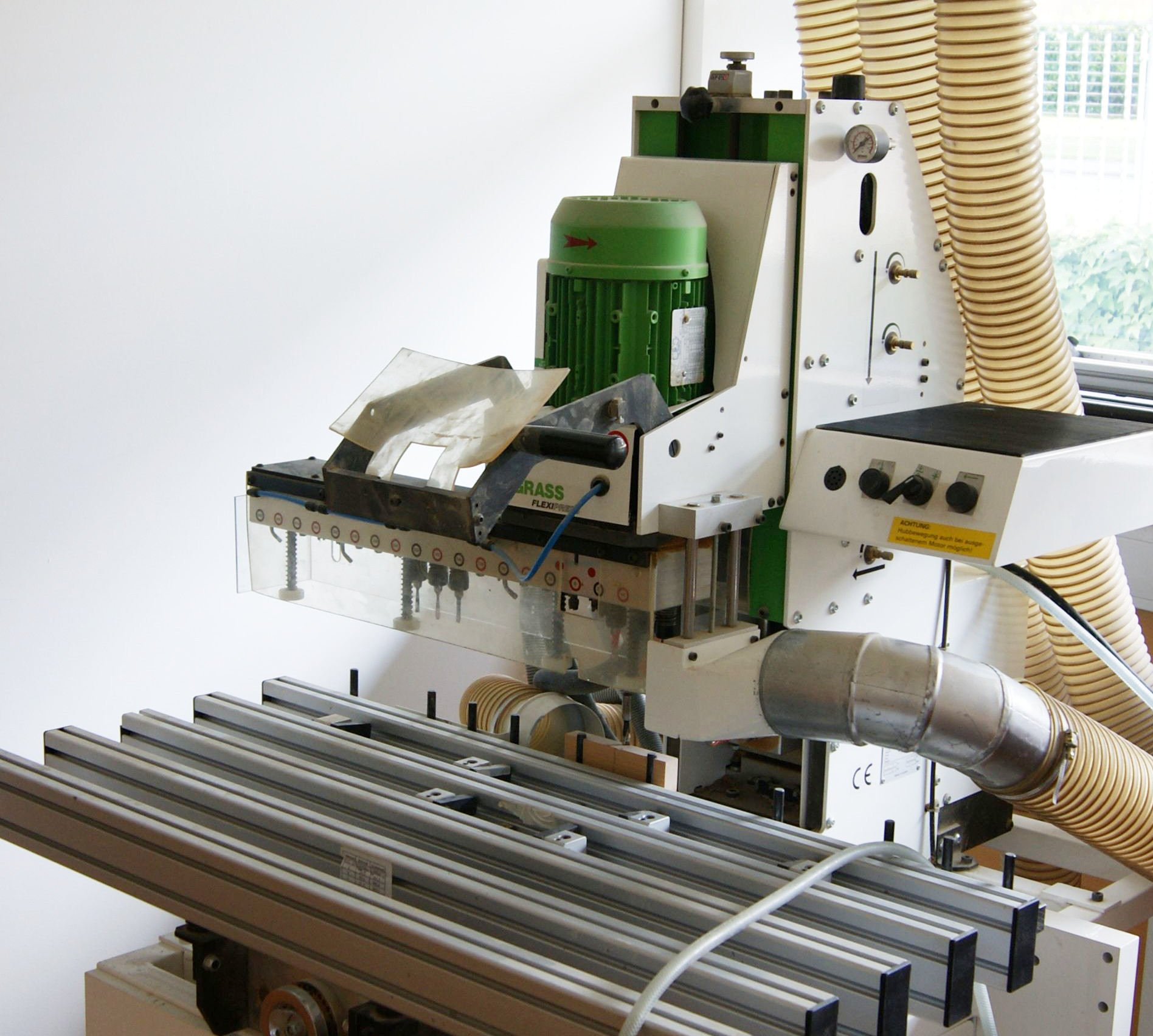

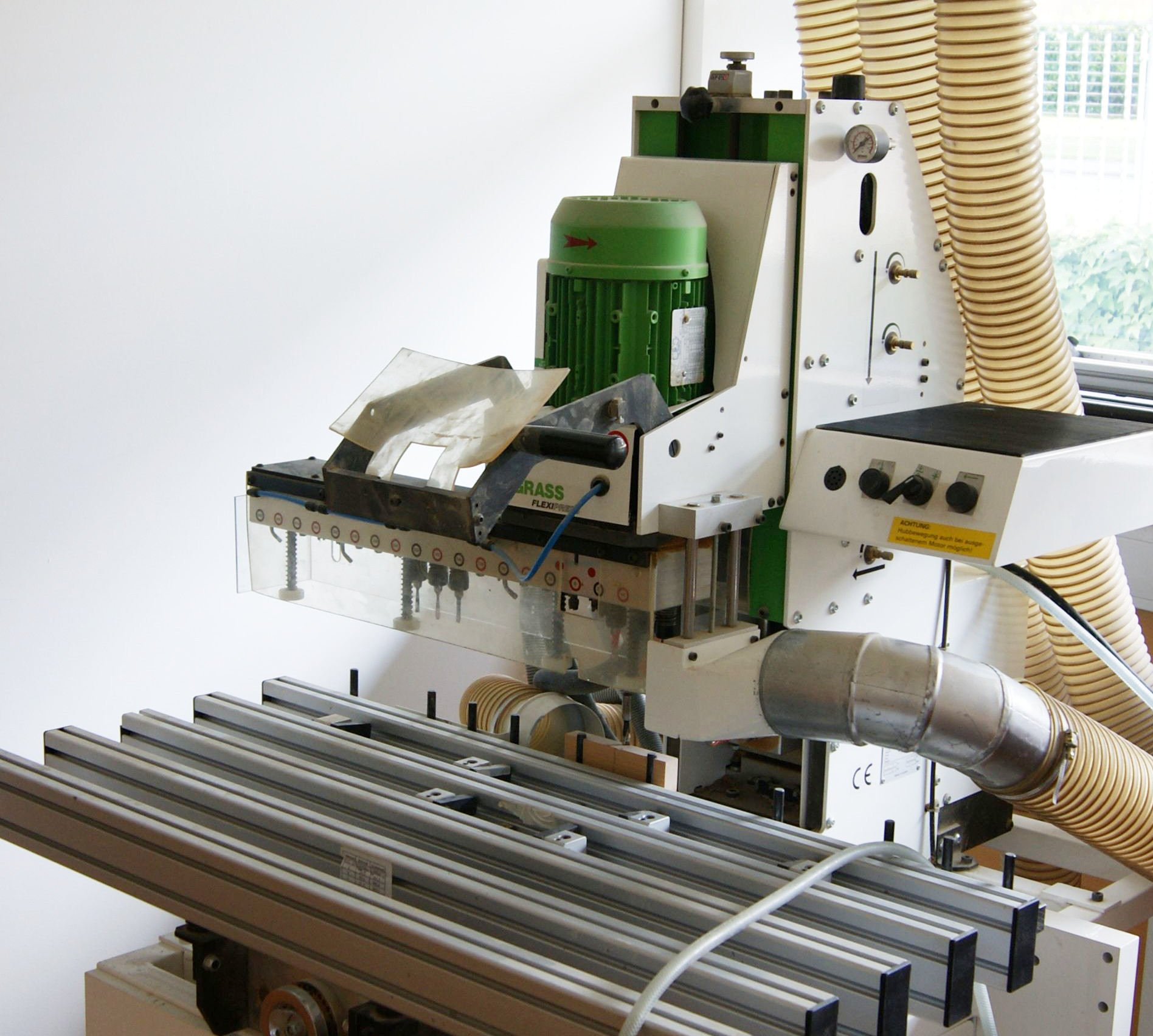

Boring machines are powerful tools used in various industries to create precise and accurate holes in materials. These machines are designed to remove material from the workpiece, leaving behind a perfectly shaped hole. They are commonly used in manufacturing, construction, and mining industries. Boring machines come in different types, such as horizontal boring machines, vertical boring machines, and tunnel boring machines. Each type has its own unique features and applications. With their advanced technology and versatility, boring machines have revolutionized the way industries operate. They provide efficient and cost-effective solutions for drilling holes of different sizes and depths. Whether it’s for creating tunnels, installing pipelines, or manufacturing complex components, boring machines play a crucial role in modern industries.

History of boring machines

Boring machines have a fascinating history that dates back several centuries. These incredible machines have played a crucial role in shaping various industries and have revolutionized the way we create and manufacture products. The origins of boring machines can be traced back to ancient civilizations, where early inventors developed primitive tools to excavate tunnels and create underground passageways. Over time, these tools evolved and became more sophisticated, leading to the development of the modern boring machines we know today. Today, boring machines are used in a wide range of industries, including construction, mining, and manufacturing. They are capable of drilling precise holes, creating tunnels, and even excavating large areas of land. The history of boring machines is a testament to human ingenuity and the relentless pursuit of innovation.

Importance of boring machines in industries

Boring machines play a crucial role in industries by providing efficient and precise drilling solutions. These machines are used for various applications such as creating holes, enlarging existing holes, and boring tunnels. The importance of boring machines in industries cannot be overstated as they enable the production of complex and accurate components that are essential for the functioning of many industries. With their advanced technology and versatility, boring machines have revolutionized the manufacturing process, increasing productivity and reducing manual labor. Industries rely on these machines to achieve high-quality results and meet the demands of modern production. Bold keywords: boring machines, industries, efficient, precise drilling solutions, holes, tunnels, importance, complex and accurate components, advanced technology, versatility, manufacturing process, productivity, manual labor, high-quality results, modern production.

Applications of Boring Machines

Boring machines in construction industry

Boring machines have revolutionized the construction industry with their remarkable capabilities. These machines are specifically designed to create precise and accurate holes in various materials, making them indispensable in construction projects. Whether it’s drilling holes for foundations, tunnels, or pipelines, boring machines offer unmatched efficiency and accuracy. With their powerful motors and advanced drilling mechanisms, these machines can effortlessly penetrate even the toughest materials, saving both time and effort. The construction industry heavily relies on boring machines for their ability to create holes of different sizes and depths, allowing for the installation of crucial infrastructure components. From skyscrapers to bridges, boring machines play a vital role in shaping our modern world.

Boring machines in mining industry

Boring machines play a crucial role in the mining industry. These powerful machines are used to create tunnels and boreholes in the earth, allowing access to valuable resources such as coal, gold, and minerals. With their advanced drilling capabilities, boring machines can penetrate even the toughest rock formations, making mining operations more efficient and productive. The use of boring machines in the mining industry has revolutionized the way resources are extracted, leading to increased safety, reduced costs, and improved environmental sustainability. Bold keywords: boring machines, mining industry, tunnels, boreholes, valuable resources, coal, gold, minerals, drilling capabilities, rock formations, mining operations, efficient, productive, safety, costs, environmental sustainability.

Boring machines in automotive industry

Boring machines have revolutionized the automotive industry, providing precise and efficient solutions for various manufacturing processes. These powerful machines are capable of creating precise holes and bores in metal and other materials, ensuring the accuracy and quality of automotive components. With their advanced technology and high-speed capabilities, boring machines have become an indispensable tool in the production of engine blocks, cylinder heads, and other critical automotive parts. By using boring machines, manufacturers can achieve tight tolerances and superior surface finishes, resulting in enhanced performance and durability of vehicles. Whether it’s boring engine cylinders or creating intricate patterns on car body panels, these machines offer endless possibilities for innovation and design. BoldKeywords Boring machines, automotive industry, precise holes, manufacturing processes, engine blocks, cylinder heads, critical automotive parts, tight tolerances, superior surface finishes, enhanced performance, durability of vehicles, innovation, design

Advantages of Boring Machines

Increased efficiency and productivity

Boring machines have revolutionized the industrial sector by significantly increasing efficiency and productivity. These machines, equipped with advanced technology and precision engineering, have become indispensable in various industries. With their ability to perform complex tasks with utmost accuracy, boring machines have streamlined production processes and reduced human error. The use of boring machines has also led to significant time savings, as they can complete tasks that would otherwise take hours or even days to complete manually. This increased efficiency has not only improved productivity but has also allowed industries to meet growing demands and stay competitive in the market. The incorporation of boring machines in industries has proven to be a game-changer, enabling companies to achieve higher output, reduce costs, and deliver high-quality products to their customers.

Accurate and precise drilling

Boring machines are revolutionizing industries with their accurate and precise drilling capabilities. These powerful machines are capable of drilling holes with incredible precision, ensuring that every hole is perfectly aligned and sized. The accuracy of boring machines is unmatched, making them an indispensable tool in various industries. Whether it’s drilling holes for pipelines, tunnels, or foundations, boring machines deliver exceptional results every time. With their ability to bore through different materials, such as metal, wood, and concrete, these machines offer versatility and efficiency. Companies across industries rely on boring machines to achieve the highest level of accuracy in their drilling operations.

Cost savings and reduced labor

Boring machines have revolutionized the industrial sector by providing cost savings and reducing the need for manual labor. These machines are equipped with advanced technology and precision engineering, allowing them to perform tasks with incredible accuracy and efficiency. By automating the boring process, companies can significantly reduce the time and effort required to complete projects, resulting in substantial cost savings. Additionally, the use of boring machines eliminates the need for manual labor, reducing the risk of human error and increasing overall productivity. With their ability to handle complex tasks and deliver consistent results, boring machines have become an indispensable tool in various industries.

Challenges and Limitations

Complex setup and operation

Boring machines are widely used in industries for various applications. One of the most complex aspects of using boring machines is the setup and operation. This requires skilled technicians who can handle the intricate machinery and ensure precise measurements. The setup process involves aligning the machine, securing the workpiece, and configuring the cutting tools. Once the setup is complete, the operation begins, where the machine removes material from the workpiece to create holes or enlarge existing ones. It is crucial to follow strict safety protocols during the operation to prevent accidents. The complex setup and operation of boring machines make them indispensable tools in industries that require precise drilling and machining.

Limited accessibility in certain environments

Limited accessibility in certain environments is a common challenge faced by industries. In areas with narrow spaces or difficult terrains, traditional machines often struggle to reach and operate effectively. However, boring machines have emerged as a solution to this problem. These machines are specifically designed to navigate through tight spaces and challenging environments, allowing industries to carry out their operations without hindrance. With their compact size and advanced maneuverability, boring machines can access areas that were previously inaccessible, opening up new possibilities for industries. Whether it’s drilling tunnels in mountainous regions or excavating underground spaces, boring machines offer a reliable and efficient solution. By utilizing these machines, industries can overcome the limitations posed by restricted accessibility and maximize their productivity.

Maintenance and repair requirements

Maintenance and repair requirements for boring machines are crucial to ensure their optimal performance and longevity. Regular maintenance tasks include lubricating moving parts, inspecting and replacing worn-out components, and calibrating the machine for accurate drilling. Additionally, it is important to schedule periodic inspections by qualified technicians to identify and address any potential issues before they escalate. Adhering to the manufacturer’s guidelines and recommendations is essential to maintain the machine’s warranty and prevent costly breakdowns. By prioritizing maintenance and repair, industries can minimize downtime, increase productivity, and extend the lifespan of their boring machines.

Future Developments in Boring Machines

Automation and robotics integration

Automation and robotics integration has revolutionized the industrial sector. With the advent of advanced technologies, boring machines have become an integral part of industries. These machines automate the process of drilling, cutting, and shaping materials, increasing productivity and efficiency. They are capable of performing repetitive tasks with precision and accuracy, reducing the need for manual labor. By integrating robotics with boring machines, industries have achieved higher levels of automation, leading to cost savings and improved quality. This integration has also enhanced worker safety by eliminating the need for human operators to be in close proximity to the machines. The use of boring machines in industries has opened up new possibilities for innovation and has paved the way for increased production capabilities. With the ability to handle various materials and perform complex operations, boring machines have become indispensable tools in modern manufacturing.

Enhanced drilling capabilities

Boring machines have revolutionized the drilling industry with their enhanced drilling capabilities. These machines are equipped with advanced features that allow for precise and efficient drilling operations. With their powerful motors and specialized drill bits, boring machines can easily penetrate through tough materials like concrete, metal, and wood. This makes them an indispensable tool in various industries such as construction, mining, and manufacturing. The enhanced drilling capabilities of boring machines have greatly improved productivity and efficiency in these industries, saving both time and money. Additionally, these machines offer a high level of accuracy, ensuring that the drilled holes are perfectly aligned and of the desired depth. With their ability to handle a wide range of drilling tasks, boring machines have become a go-to solution for professionals in need of reliable and efficient drilling equipment.

Improved safety features

Boring machines have revolutionized the industrial sector with their improved safety features. These machines are equipped with advanced technologies that ensure the well-being of workers and prevent accidents. With features like automatic shut-off systems, emergency stop buttons, and safety sensors, boring machines prioritize the safety of operators. The incorporation of boldKeywords such as safety gear, protective shields, and safety training further enhances the safety measures in place. Workers can now operate these machines with confidence, knowing that their safety is a top priority. The implementation of improved safety features in boring machines has significantly reduced workplace accidents and injuries, making them an invaluable asset to industries.

Conclusion

Boring machines revolutionize industries

Boring machines have revolutionized industries by providing efficient and precise drilling solutions. With their advanced technology and powerful capabilities, these machines have become indispensable in various sectors. From construction to manufacturing, boring machines have significantly improved productivity and accuracy. They are capable of drilling holes of different sizes and depths, making them ideal for a wide range of applications. The use of boring machines has not only reduced manual labor but also minimized errors, resulting in cost savings and enhanced quality. These machines have truly transformed the way industries operate, making them a vital tool in today’s modern world.

Continuous advancements drive innovation

Continuous advancements in technology have always been a driving force behind innovation in various industries. Boring machines, with their ability to efficiently excavate tunnels and create boreholes, have played a significant role in revolutionizing the construction and mining sectors. These machines have been instrumental in the development of infrastructure projects such as underground railways, highways, and pipelines. Additionally, their precision and accuracy have made them indispensable in the manufacturing industry, where they are used for creating precise holes and tunnels in metal and other materials. With continuous advancements in boring machine technology, industries can expect even more innovative applications in the future.

Exciting future prospects for boring machines

Boring machines have come a long way in revolutionizing various industries. With their ability to create precise and accurate holes, these machines have become an indispensable tool in the manufacturing sector. But what does the future hold for these seemingly mundane machines? Well, brace yourselves for some exciting prospects! The advancements in technology are opening up new possibilities for boring machines. From automated operations to enhanced precision, these machines are set to take productivity to a whole new level. Imagine a future where boring machines can seamlessly integrate with other cutting-edge technologies like artificial intelligence and robotics. This integration would not only streamline the manufacturing process but also optimize efficiency and reduce costs. So, get ready to witness a future where boring machines become the unsung heroes of the industrial world!

by Mud@r_M1 | Nov 25, 2023 | Information

Overview

What is a Jig Borer?

A jig borer is a precision machine tool used in metalworking that is valued for its versatility. It is commonly used to create highly accurate holes and contours in a variety of materials, including metal, plastic, and wood. The jig borer operates by using a single-point cutting tool that moves in a linear or rotary motion to remove material from the workpiece. This allows for precise and repeatable machining operations, making it an indispensable tool for many industries. With its ability to handle complex tasks and deliver precise results, the jig borer is a must-have for any serious metalworker.

History of Jig Borers

Jig borers have a rich history that dates back to the early 20th century. These versatile machines were initially developed for the precision machining of metal parts. They quickly gained popularity due to their ability to accurately drill, bore, and mill holes with high precision. The history of jig borers is closely intertwined with the evolution of metalworking technology, as these machines played a crucial role in advancing the field. Over the years, jig borers have undergone significant improvements and innovations, making them an indispensable tool in various industries today.

Importance of Jig Borers in Metalworking

Jig borers are an essential tool in metalworking, providing unmatched precision and versatility. These machines play a crucial role in creating intricate and complex parts with utmost accuracy. The importance of jig borers in metalworking cannot be overstated. From drilling precise holes to shaping intricate profiles, jig borers offer a wide range of capabilities that traditional machining methods simply cannot match. With their ability to hold tight tolerances and deliver consistent results, jig borers are a must-have for any metalworking professional. Whether you’re working on a small-scale project or tackling a large manufacturing job, the versatility of jig borers ensures that you can achieve the desired results with ease.

Precision Machining with Jig Borers

Understanding the Basics of Jig Boring

Jig boring is a crucial process in metalworking that involves creating highly precise and accurate holes in a workpiece. It is a specialized form of boring that utilizes a single-point cutting tool called a jig borer. Understanding the basics of jig boring is essential for any metalworker looking to achieve exceptional precision and quality in their work. By using a jig borer, metalworkers can create holes with tight tolerances and smooth finishes, ensuring proper fit and functionality of the final product. The versatility of jig borers allows for a wide range of applications, from creating holes in small delicate parts to large and complex workpieces. With its ability to produce holes of various sizes and shapes, jig boring is a valuable technique in industries such as aerospace, automotive, and manufacturing. By mastering the basics of jig boring, metalworkers can elevate their craftsmanship and deliver outstanding results.

Advantages of Jig Borers in Precision Machining

Jig borers are an essential tool in precision machining, offering a wide range of advantages. These versatile machines provide exceptional accuracy and precision, making them ideal for intricate and complex metalworking tasks. With their ability to drill, bore, and mill with high precision, jig borers enable the creation of intricate patterns, holes, and contours with ease. The use of jig borers in metalworking not only ensures the production of precise and high-quality components but also enhances efficiency and productivity in the manufacturing process. The ability to work with various materials, including metals, plastics, and composites, further adds to the versatility of jig borers. Whether it’s creating intricate parts for aerospace applications or crafting precision components for medical devices, jig borers prove their worth in a wide range of industries. With their exceptional precision and versatility, jig borers are a valuable asset for any metalworking operation.

Applications of Jig Borers in Various Industries

Jig borers are incredibly versatile machines that have revolutionized the metalworking industry. With their precise drilling capabilities and ability to create intricate patterns, jig borers have found applications in various industries. From aerospace to automotive, these machines have become indispensable tools for creating high-quality products. In the aerospace industry, jig borers are used to create precise holes in aircraft components, ensuring the safety and reliability of the final product. In the automotive industry, jig borers are used for machining engine blocks and other critical components, improving performance and efficiency. Additionally, jig borers are also used in the electronics industry for creating circuit boards with precision. The versatility of jig borers is unmatched, making them a valuable asset in metalworking.

Enhancing Accuracy with Jig Borers

The Role of Jig Borers in Achieving High Precision

Jig borers play a crucial role in achieving high precision in metalworking. With their exceptional versatility and accuracy, these machines have become an indispensable tool for machinists and manufacturers alike. Whether it’s drilling precise holes, creating intricate patterns, or shaping complex surfaces, jig borers deliver unparalleled results. The ability to achieve tight tolerances and maintain consistent quality makes them a preferred choice for projects that demand utmost precision. With their advanced features and robust construction, jig borers ensure that every component produced meets the highest standards of accuracy and reliability. So, if you’re looking to take your metalworking to the next level, harness the power of jig borers and experience the difference in precision and performance.

Techniques for Improving Accuracy with Jig Borers

Jig borers are incredibly versatile machines in the metalworking industry. They offer a wide range of techniques for improving accuracy, making them an essential tool for precision work. By utilizing advanced measuring systems and adjustable components, jig borers can achieve precise hole positioning and dimensioning. Additionally, the use of specialized attachments and accessories allows for the creation of complex shapes and contours. These machines are also known for their ability to maintain consistent accuracy over long periods of time, ensuring reliable and repeatable results. Whether you’re working on small-scale projects or large-scale productions, jig borers are a valuable asset for achieving high levels of precision and accuracy.

Case Studies: How Jig Borers Have Improved Accuracy in Metalworking

Jig borers are a highly versatile tool in the field of metalworking. With their precision and accuracy, they have revolutionized the way metal parts are manufactured. In this article, we will explore some case studies that highlight how jig borers have improved accuracy in metalworking. These real-life examples demonstrate the impact of using jig borers in various industries, from aerospace to automotive. By utilizing jig borers, manufacturers have been able to achieve tighter tolerances and higher quality finishes, resulting in improved product performance. So, let’s dive into these fascinating case studies and discover the incredible versatility of jig borers in metalworking!

Versatility of Jig Borers

Beyond Precision Machining: Other Applications of Jig Borers

Jig borers, often associated with precision machining, have a wide range of applications beyond their primary purpose. These versatile machines can be used for various tasks, making them a valuable asset in metalworking. One of the key advantages of jig borers is their ability to perform intricate drilling operations with utmost precision. Whether it’s creating precise holes, shaping complex profiles, or even engraving intricate designs, jig borers excel in delivering exceptional results. But did you know that jig borers can also be used for other applications? From milling and boring to reaming and tapping, these machines offer a plethora of possibilities. With their accurate positioning and rigid construction, jig borers can tackle a variety of metalworking tasks with ease. So, the next time you think of precision machining, remember that jig borers are not just limited to that. They are versatile tools that can take your metalworking projects to the next level.

Customization and Adaptability of Jig Borers

Jig borers are incredibly versatile machines in the field of metalworking. They offer a wide range of customization and adaptability options, making them a valuable tool for various applications. Whether it’s drilling precise holes, creating intricate shapes, or performing accurate measurements, jig borers can handle it all. With their precise movements and adjustable features, these machines allow for precise and efficient metalworking processes. The ability to customize and adapt jig borers to specific requirements ensures that they can meet the unique needs of different projects. From small-scale workshops to large industrial settings, jig borers are indispensable tools that enhance productivity and quality in metalworking.

Exploring the Limitless Possibilities with Jig Borers

Jig borers are an essential tool in the metalworking industry, offering limitless possibilities for precision machining. With their versatile design and precise movements, jig borers enable engineers and machinists to create intricate and complex parts with ease. From drilling holes to shaping intricate contours, jig borers can handle a wide range of tasks, making them a valuable asset in any metalworking workshop. Whether you’re working on a small-scale project or tackling a large production run, jig borers provide the accuracy and efficiency needed to get the job done right. So, if you’re looking to explore the limitless possibilities in metalworking, look no further than jig borers.

Choosing the Right Jig Borer for Your Needs

Factors to Consider When Selecting a Jig Borer

When selecting a jig borer, there are several factors to consider. First and foremost, it is important to assess the size and weight of the workpieces that will be machined. The jig borer should have a sufficient table size and weight capacity to accommodate the workpieces. Additionally, the spindle speed and power of the jig borer are crucial factors to ensure efficient and accurate machining. It is also essential to evaluate the accuracy and precision of the jig borer, as well as the availability of advanced features such as digital readouts and tooling options. Finally, considering the cost and maintenance requirements of the jig borer is important to make an informed decision. By carefully considering these factors, you can select a jig borer that meets your specific metalworking needs.

Different Types of Jig Borers and Their Features

Jig borers are essential tools in the field of metalworking due to their versatility and precision. These machines come in various types, each with its own unique features and capabilities. One type is the vertical jig borer, which is known for its ability to drill holes vertically with great accuracy. Another type is the horizontal jig borer, which is designed for machining large workpieces. There are also CNC jig borers, which use computer numerical control to automate the drilling process. Regardless of the type, jig borers are widely used in industries such as aerospace, automotive, and manufacturing, where precision and efficiency are paramount. With their ability to perform intricate drilling operations and produce high-quality results, jig borers are an indispensable tool for metalworkers.

Tips for Making an Informed Decision

When it comes to making an informed decision about jig borers in metalworking, there are a few key tips to keep in mind. First, it’s important to research different brands and models to find the one that best suits your needs. Look for features such as precision, durability, and versatility. Additionally, consider the size and weight of the jig borer, as well as any additional accessories or attachments that may be available. Another tip is to read reviews and testimonials from other metalworkers who have used the jig borers you are considering. This can provide valuable insights and help you make a more informed decision. Lastly, don’t forget to consider your budget. While quality and performance are important, it’s also essential to find a jig borer that fits within your price range. By following these tips, you can make an informed decision and choose a jig borer that will meet your metalworking needs.

Conclusion

The Future of Jig Borers in Metalworking

Jig borers have been a staple in metalworking for decades, providing precision and accuracy in drilling and milling operations. But what does the future hold for these versatile machines? With advancements in technology and the increasing demand for complex and intricate metal parts, jig borers are poised to play a crucial role in the future of metalworking. The combination of their precision, versatility, and ability to work with a wide range of materials makes them an invaluable tool for industries such as aerospace, automotive, and manufacturing. As the industry continues to evolve, jig borers will continue to adapt and improve, ensuring that they remain a vital component of metalworking processes. So, whether you’re a seasoned professional or just starting out in the field, it’s clear that the future of jig borers in metalworking is bright and full of possibilities.

Continued Innovation and Advancements in Jig Boring Technology

Jig borers have long been a staple in metalworking, providing precise drilling and boring capabilities. However, the continued innovation and advancements in jig boring technology have taken this versatile tool to new heights. With improved accuracy, speed, and efficiency, modern jig borers are able to tackle even the most complex machining tasks with ease. From aerospace to automotive industries, these machines play a crucial role in creating intricate parts and components. The incorporation of computer numerical control (CNC) systems has further enhanced the capabilities of jig borers, allowing for automated operations and increased productivity. As technology continues to evolve, we can expect further advancements in jig boring technology, making it an indispensable tool in the metalworking industry.

Embracing the Versatility and Precision of Jig Borers

Jig borers are an indispensable tool in the world of metalworking. Their versatility and precision make them a favorite among both hobbyists and professionals. Whether you’re drilling, milling, or boring, jig borers can handle it all with ease. With their ability to accurately position and guide cutting tools, they ensure that every operation is performed with utmost precision. From creating intricate patterns to shaping complex parts, jig borers are the go-to choice for achieving the highest level of accuracy. Embracing the versatility and precision of jig borers opens up a whole new world of possibilities in metalworking.

by Mud@r_M1 | Nov 25, 2023 | Information

Overview

Introduction to horizontal and vertical boring machines

Horizontal and vertical boring machines are essential tools in the manufacturing and construction industries. These machines are used to create holes in various materials, such as wood, metal, and concrete. The main difference between horizontal and vertical boring machines lies in the orientation of the spindle. In horizontal machines, the spindle is positioned horizontally, while in vertical machines, the spindle is positioned vertically. Both types of machines have their advantages and are suitable for different applications. Let’s explore the features and benefits of each type in detail.

Key differences between horizontal and vertical boring machines

Horizontal and vertical boring machines have several key differences that make each type suitable for different applications. One of the main differences is the orientation of the spindle. In horizontal boring machines, the spindle is positioned horizontally, parallel to the ground. This allows for the drilling of holes or cutting of slots in a horizontal direction. On the other hand, vertical boring machines have a spindle that is positioned vertically, perpendicular to the ground. This orientation enables the drilling or cutting of holes in a vertical direction. Another significant difference is the size and weight of the workpieces that can be accommodated. Horizontal boring machines are typically used for larger and heavier workpieces, while vertical boring machines are more suitable for smaller and lighter workpieces. Additionally, the type of operations that can be performed also varies between the two types of machines. Horizontal boring machines are often used for milling, boring, and drilling operations, while vertical boring machines are commonly used for turning operations. Overall, the choice between horizontal and vertical boring machines depends on the specific requirements of the application and the characteristics of the workpiece.

Importance of choosing the right boring machine for your needs

Choosing the right boring machine for your needs is of utmost importance. Whether you’re working on a construction project or a woodworking project, the type of machine you use can greatly impact the outcome. Horizontal and vertical boring machines each have their own advantages and disadvantages. Understanding these differences will help you make an informed decision. So, let’s dive into the world of boring machines and explore which one is better for you.

Advantages of Horizontal Boring Machines

Increased stability and precision

When it comes to boring machines, one of the key factors to consider is increased stability and precision. Both horizontal and vertical boring machines offer their own advantages in this regard. Horizontal boring machines provide a stable and rigid platform for drilling and boring operations, ensuring precise and accurate results. On the other hand, vertical boring machines excel in providing enhanced stability, especially when dealing with larger and heavier workpieces. This increased stability translates into improved precision and eliminates the risk of vibrations that can affect the quality of the work. Whether you choose a horizontal or vertical boring machine, you can be confident in achieving the level of stability and precision required for your specific applications.

Ability to handle larger workpieces

When it comes to the ability to handle larger workpieces, both horizontal and vertical boring machines have their advantages. Horizontal boring machines are known for their ability to handle long and heavy workpieces with ease. They are ideal for projects that require precision and stability. On the other hand, vertical boring machines excel at handling taller workpieces. Their vertical design allows for easy maneuverability and accessibility. Whether you need to bore large cylindrical parts or work on tall structures, both types of machines have the capabilities to get the job done.

Efficient chip evacuation

Efficient chip evacuation is a crucial factor to consider when choosing between horizontal and vertical boring machines. These machines are designed to remove material from a workpiece, and the chips produced during the process need to be effectively evacuated to ensure smooth and efficient operations. Horizontal boring machines excel in chip evacuation due to their horizontal orientation, which allows gravity to help in the removal of chips. On the other hand, vertical boring machines rely on chip conveyors or augers to transport the chips away from the workpiece. Both methods have their advantages and disadvantages, and the choice depends on the specific requirements of the application. However, it is important to note that proper chip evacuation is essential to maintain the performance and longevity of the machine.

Disadvantages of Horizontal Boring Machines

Limited vertical reach

Limited vertical reach is one of the key factors to consider when choosing between horizontal and vertical boring machines. While horizontal boring machines offer a wide range of movement in all directions, vertical boring machines have a more limited vertical reach. This means that vertical boring machines may not be suitable for projects that require deep drilling or the ability to reach high areas. However, for projects that involve shallow drilling or require precision in a specific vertical range, vertical boring machines can be a better choice. It’s important to assess the specific requirements of your project and determine whether the limited vertical reach of a vertical boring machine will meet your needs.

Higher initial cost

When it comes to choosing between horizontal and vertical boring machines, one important factor to consider is the higher initial cost. While both types of machines have their advantages, the initial investment required for a vertical boring machine is typically higher than that of a horizontal boring machine. This is due to the additional components and features that are often included in vertical machines to accommodate the vertical drilling process. However, it’s important to note that the higher initial cost may be justified by the increased productivity and versatility that a vertical boring machine can offer. So, if you’re looking for a machine that can handle a wide range of drilling tasks and provide efficient and precise results, a vertical boring machine may be the better option for you.

Requires more floor space

Horizontal boring machines are known for their ability to perform precise and accurate drilling operations. However, one drawback of these machines is that they require more floor space compared to vertical boring machines. This is because horizontal boring machines have a larger footprint due to their design and construction. The extra floor space needed may pose a challenge for smaller workshops or facilities with limited space. On the other hand, vertical boring machines have a smaller footprint and can be a more practical choice for those with space constraints. Therefore, when considering which type of boring machine to use, it is important to take into account the available floor space and the specific requirements of the drilling operations.

Advantages of Vertical Boring Machines

Greater flexibility in terms of workpiece size

Horizontal and vertical boring machines both have their advantages and are suitable for different types of work. However, when it comes to greater flexibility in terms of workpiece size, the horizontal boring machine takes the lead. With its horizontal orientation, this machine allows for larger workpieces to be accommodated, making it ideal for projects that require working with oversized materials. Whether you’re working on a large-scale construction project or creating custom furniture pieces, the horizontal boring machine offers the versatility and adaptability needed to handle a wide range of workpiece sizes.

Ability to perform multiple operations

Horizontal and vertical boring machines both have their own unique advantages and capabilities. One important factor to consider when comparing the two is their ability to perform multiple operations. Horizontal boring machines are known for their versatility, as they can perform a wide range of operations such as drilling, milling, and tapping. On the other hand, vertical boring machines excel in performing operations that require deep hole drilling and precision machining. Both types of machines have their strengths and can be used effectively depending on the specific requirements of the project. It’s important to understand the capabilities of each machine and choose the one that best suits the desired operations.

Smaller footprint

When it comes to choosing between horizontal and vertical boring machines, one important factor to consider is the smaller footprint. A smaller footprint means that the machine takes up less space in your workshop or factory, allowing you to maximize the use of your available space. This can be especially beneficial if you have limited space or if you want to optimize the layout of your workspace. With a smaller footprint, you can easily fit the machine into tight spaces and still have room for other equipment or workstations. Additionally, a smaller footprint can also lead to cost savings, as you may not need to invest in additional space or make modifications to your existing layout. So, if space efficiency is a priority for you, a machine with a smaller footprint may be the better choice.

Disadvantages of Vertical Boring Machines

Less stability compared to horizontal machines

When it comes to stability, vertical boring machines have less stability compared to horizontal machines. This is due to the vertical orientation of the spindle, which can result in more vibrations and less rigidity during machining operations. While vertical machines are still capable of performing a wide range of tasks, including drilling, milling, and boring, their design inherently limits their stability. On the other hand, horizontal boring machines offer superior stability thanks to their horizontal spindle orientation. This allows for more precise and accurate machining, particularly for heavy-duty applications. With horizontal machines, operators can confidently tackle large-scale projects with minimal vibrations and maximum stability.

Limited capacity for large workpieces

When it comes to boring machines, one important factor to consider is their capacity for handling large workpieces. While both horizontal and vertical boring machines have their advantages, they also have limitations when it comes to working with large workpieces. Horizontal boring machines, for example, may have a limited capacity for accommodating oversized workpieces due to their design and structure. On the other hand, vertical boring machines may have a higher capacity for larger workpieces, but they may be limited in terms of the height of the workpiece that can be accommodated. Therefore, it is crucial to carefully assess the capacity of the boring machine to ensure it can handle the size of the workpieces you need to work with.

Less efficient chip evacuation

When it comes to chip evacuation, horizontal and vertical boring machines have different levels of efficiency. While both types of machines are capable of removing chips from the workpiece, horizontal boring machines generally have a slight advantage in this aspect. The horizontal orientation allows for better gravity-assisted chip evacuation, ensuring that the chips are efficiently cleared away from the cutting area. On the other hand, vertical boring machines may require additional measures, such as coolant or air blasts, to aid in chip removal. Therefore, if efficient chip evacuation is a priority, opting for a horizontal boring machine might be the better choice.

Conclusion

Consider your specific needs and requirements

When choosing between horizontal and vertical boring machines, it is important to consider your specific needs and requirements. These machines offer different advantages and are suitable for different applications. If you need to bore large, heavy workpieces, a horizontal boring machine may be the better choice. It allows for the horizontal movement of the spindle, making it easier to handle heavy loads. On the other hand, if you need to bore deep, narrow holes, a vertical boring machine may be more suitable. Its vertical spindle movement allows for precise drilling in tight spaces. Ultimately, the decision depends on the specific tasks you need to accomplish and the type of workpieces you will be working with. By carefully considering your needs and requirements, you can choose the right boring machine that will best meet your needs.

Evaluate the pros and cons of each type of machine

Horizontal boring machines and vertical boring machines are two popular options in the manufacturing industry. Each type of machine has its own set of pros and cons that should be carefully evaluated. Let’s take a closer look at the advantages and disadvantages of each. Horizontal boring machines offer versatility and flexibility. They are capable of handling large and heavy workpieces, making them ideal for industries such as construction and aerospace. Additionally, horizontal machines allow for precise drilling and milling operations. On the other hand, vertical boring machines are known for their compact size and cost-effectiveness. They take up less floor space and are generally more affordable compared to horizontal machines. Vertical machines are often used for smaller workpieces and are suitable for industries such as automotive and electronics. In conclusion, the choice between horizontal and vertical boring machines depends on the specific needs and requirements of the project. Both types have their own advantages and disadvantages, and it is important to carefully evaluate them before making a decision.

Choose the machine that best suits your application

When it comes to choosing between horizontal and vertical boring machines, it’s important to consider the specific needs of your application. Both types of machines have their own advantages and disadvantages, so it’s crucial to understand which one will best suit your requirements. Horizontal boring machines are known for their stability and precision, making them ideal for larger projects that require accuracy. On the other hand, vertical boring machines are more versatile and can handle a wider range of materials and sizes. Ultimately, the decision should be based on factors such as the size of your workpiece, the type of material you’re working with, and the level of precision you require. By carefully considering these factors, you can choose the machine that will deliver the best results for your application.

by Mud@r_M1 | Nov 25, 2023 | Information

Overview

What are slotting metalworking machines?

Slotting metalworking machines are versatile tools used in various industries for cutting, shaping, and slotting metal workpieces. These machines are equipped with adjustable features that allow operators to customize the stroke length, ensuring precise and accurate cuts. The stroke length refers to the distance the cutting tool travels during each cycle, and it plays a crucial role in determining the depth and width of the slots created. With the ability to adjust the stroke length, operators have the flexibility to accommodate different workpiece sizes and achieve desired slot dimensions. Whether it’s creating keyways, grooves, or internal slots, slotting metalworking machines provide the necessary power and precision to meet the demands of metal fabrication. By understanding the adjustable features and stroke length of these machines, operators can optimize their productivity and deliver high-quality results.

Importance of stroke length in slotting machines

The stroke length is a crucial factor in slotting machines as it determines the maximum distance the cutting tool can travel vertically. This adjustable feature allows for greater flexibility in the machining process, enabling the creation of slots with varying depths. The importance of stroke length lies in its ability to accommodate different workpiece sizes and material thicknesses, making it a key consideration in metalworking operations. By adjusting the stroke length, operators can optimize the machine’s performance and achieve precise and accurate slotting results. This feature also contributes to the overall efficiency and productivity of the slotting machine, as it reduces the need for manual adjustments and enhances the machine’s adaptability to different machining requirements. Therefore, understanding the importance of stroke length in slotting machines is essential for maximizing productivity and achieving high-quality slotting outcomes.

Adjustable features of slotting machines

Slotting machines are versatile metalworking machines that offer a range of adjustable features. These features allow operators to customize the machine’s performance and adapt it to specific machining requirements. One important adjustable feature is the stroke length, which determines the distance the cutting tool travels during each cycle. By adjusting the stroke length, operators can control the depth and length of the slots or grooves created by the machine. Other adjustable features include the speed of the cutting tool, the feed rate, and the table movement. These features give operators the flexibility to achieve precise and accurate results. Whether it’s creating keyways, splines, or internal slots, slotting machines with adjustable features provide a reliable and efficient solution for metalworking tasks.

Understanding Stroke Length

Definition and purpose of stroke length

The stroke length is a crucial parameter in slotting metalworking machines. It refers to the distance that the ram or tool moves during each stroke. The stroke length determines the maximum depth of the cut that can be achieved. It is an adjustable feature that allows operators to control the size and precision of the slots created. By changing the stroke length, operators can accommodate different workpiece sizes and achieve desired slot dimensions. This feature is particularly useful in industries that require versatility and flexibility in slotting operations, such as automotive, aerospace, and manufacturing. Understanding the definition and purpose of stroke length is essential for operators to optimize the performance of slotting metalworking machines and ensure efficient and accurate slotting processes.

Factors affecting stroke length

The stroke length of slotting metalworking machines is influenced by several factors. These factors can affect the overall performance and functionality of the machines. One of the key factors affecting stroke length is the design and construction of the machine itself. Machines with adjustable features, such as the ability to vary the stroke length, offer greater flexibility and versatility in the metalworking process. Another factor that can impact stroke length is the type and thickness of the material being worked on. Different materials require different stroke lengths to achieve optimal results. Additionally, the power and speed of the machine also play a role in determining the stroke length. Machines with higher power and speed capabilities may have longer stroke lengths, allowing for more efficient and precise metalworking. Overall, understanding the factors that affect stroke length is crucial in selecting and utilizing slotting metalworking machines effectively.

Benefits of optimizing stroke length

Optimizing the stroke length of slotting metalworking machines offers several benefits. First and foremost, it allows for greater precision and accuracy in the machining process. By adjusting the stroke length to match the specific requirements of the workpiece, operators can ensure that each cut is made with the utmost precision. This not only improves the overall quality of the finished product but also reduces the likelihood of errors or defects. Additionally, optimizing stroke length can lead to increased productivity and efficiency. By maximizing the machine’s capabilities and minimizing unnecessary movements, operators can complete tasks more quickly and effectively. This not only saves time but also reduces the wear and tear on the machine, resulting in longer lifespan and reduced maintenance costs. Finally, optimizing stroke length can enhance the versatility and flexibility of slotting metalworking machines. With adjustable stroke length, operators can easily adapt the machine to different workpieces and machining requirements, allowing for greater versatility in the manufacturing process. Overall, optimizing stroke length is a crucial factor in maximizing the performance and capabilities of slotting metalworking machines.

Key Adjustable Features

Tool feed rate adjustment

Tool feed rate adjustment is a crucial aspect of slotting metalworking machines. By adjusting the feed rate, operators can control the speed at which the cutting tool moves through the material, thereby influencing the stroke length. This adjustment allows for greater precision and flexibility in the machining process, as different materials and cutting requirements may necessitate varying feed rates. Additionally, the ability to adjust the tool feed rate enhances the machine’s adaptability, enabling it to accommodate a wide range of workpieces and achieve optimal results. With this feature, operators can confidently tackle diverse metalworking tasks with ease and efficiency.

Ram speed control

Ram speed control is one of the key features of slotting metalworking machines. It allows operators to adjust the speed at which the ram moves, ensuring precise and efficient machining. By controlling the ram speed, operators can optimize the stroke length, resulting in accurate and consistent cuts. This feature is particularly useful when working with different materials or when precision is paramount. With the ability to adjust the ram speed, operators have greater control over the machining process, enhancing productivity and ensuring high-quality results. Understanding the importance of ram speed control is crucial for anyone working with slotting metalworking machines.

Table movement customization

Table movement customization is a crucial aspect of slotting metalworking machines. By allowing operators to adjust the stroke length and other features, these machines offer unparalleled flexibility and precision. With the ability to customize the table movement, operators can easily adapt to different workpieces and achieve the desired results. Whether it’s increasing the stroke length for deep slots or reducing it for shallow cuts, the adjustable features of slotting metalworking machines empower operators to optimize their machining processes. This level of customization not only enhances productivity but also ensures the highest quality of finished products. So, whether you’re a seasoned professional or a beginner in the metalworking industry, table movement customization is a game-changer that you can’t afford to overlook.

Enhancing Precision and Efficiency

Fine-tuning stroke length for accuracy

Fine-tuning the stroke length of slotting metalworking machines is crucial for achieving accurate results. By adjusting the stroke length, operators can finely control the depth and precision of the slots created. This feature allows for greater flexibility in meeting specific design requirements and ensures the production of high-quality metalwork. With the ability to customize the stroke length, operators can optimize the performance of the machines and achieve precise and consistent results. Whether it’s for creating intricate patterns or achieving tight tolerances, fine-tuning the stroke length is an essential aspect of operating slotting metalworking machines.

Optimizing adjustable features for efficiency

In order to optimize the adjustable features of slotting metalworking machines for maximum efficiency, it is important to consider the stroke length. The stroke length refers to the distance the cutting tool travels during each cycle. By adjusting the stroke length, operators can control the depth and length of the slots being cut, allowing for greater precision and flexibility in the machining process. Additionally, other adjustable features such as feed rate, tool speed, and tool pressure can also be optimized to enhance efficiency. By finding the perfect balance between these adjustable features, operators can achieve higher productivity, reduced downtime, and improved overall performance of the slotting metalworking machines.

Impact of adjustable features on productivity

The impact of adjustable features on productivity in slotting metalworking machines is significant. These machines offer a range of adjustable features that allow operators to customize the stroke length and other parameters according to the specific requirements of the task at hand. By being able to adjust these features, operators can optimize the machine’s performance and achieve higher levels of productivity. For example, by increasing the stroke length, operators can increase the amount of material removed with each stroke, resulting in faster machining times. Additionally, the ability to adjust other parameters such as feed rate and cutting speed allows operators to adapt the machine to different materials and cutting conditions, further enhancing productivity. Overall, the adjustable features of slotting metalworking machines have a direct impact on productivity, enabling operators to achieve efficient and effective machining processes.

Safety Considerations

Importance of safety measures in slotting machines

Safety measures are of utmost importance when it comes to operating slotting machines. These machines are powerful and can pose serious risks if not used correctly. It is crucial to follow safety guidelines and procedures to prevent accidents and injuries. Some key safety measures include wearing appropriate protective gear, such as gloves and safety glasses, and ensuring that the machine is properly maintained and inspected regularly. Additionally, operators should receive proper training on how to use the machine safely and be aware of potential hazards. By prioritizing safety, we can ensure a secure and efficient working environment.

Ensuring operator protection during operation

During the operation of slotting metalworking machines, it is crucial to ensure the protection of the operator. Safety measures should be implemented to minimize the risk of accidents and injuries. One of the key aspects to consider is the stroke length of the machine. The stroke length determines the distance the ram travels during each cycle, and it affects the efficiency and precision of the slotting process. Adjustable features of the machine, such as the speed and feed rate, also play a significant role in operator safety. By providing the operator with the ability to control these parameters, it allows for better customization and adaptability to different workpieces. Additionally, proper training and awareness programs should be conducted to educate operators on the safe operation of slotting metalworking machines. By prioritizing operator protection, we can ensure a safe and productive working environment.

Maintenance and inspection for safe usage

Regular maintenance and inspection are essential for ensuring the safe usage of slotting metalworking machines. By following a routine maintenance schedule, operators can identify and address any potential issues before they become major problems. This includes checking the stroke length of the machines, which determines the maximum distance the machine can move during operation. It is important to ensure that the stroke length is within the recommended range to prevent any damage or accidents. Additionally, the adjustable features of the machines should be inspected to ensure they are functioning properly. This includes checking the adjustment mechanisms for the cutting tools, feed rates, and depth of cut. By regularly inspecting and maintaining these machines, operators can ensure their safe and efficient operation.

Conclusion

Summary of stroke length and adjustable features

Stroke length and adjustable features play a crucial role in slotting metalworking machines. The stroke length refers to the distance the ram or tool travels during each stroke, while adjustable features allow operators to modify the machine’s settings to meet specific requirements. Understanding the relationship between stroke length and adjustable features is essential for optimizing machine performance and achieving desired results. By adjusting the stroke length and utilizing the adjustable features, operators can enhance productivity, accuracy, and versatility in metalworking operations. This article provides a comprehensive summary of stroke length and the various adjustable features available in slotting metalworking machines, offering valuable insights into their significance and practical applications.

Advantages of using slotting metalworking machines

Slotting metalworking machines offer several advantages that make them a valuable tool in the manufacturing industry. One of the key advantages is their adjustable features, which allow for precise control over the stroke length. This flexibility is essential for producing accurate and consistent slotting operations. Additionally, these machines are known for their durability and reliability, ensuring long-term productivity. The adjustable features also enable operators to customize the machines according to specific requirements, making them versatile for various applications. Overall, the use of slotting metalworking machines provides efficiency, precision, and versatility, making them an indispensable asset in the metalworking industry.

Future developments in slotting machine technology

In the rapidly evolving world of slotting machine technology, there are exciting developments on the horizon. Manufacturers are constantly striving to improve the performance and versatility of these machines to meet the ever-growing demands of the metalworking industry. One area of focus is stroke length, which refers to the distance the cutting tool can travel vertically. By increasing the stroke length, slotting machines can accommodate larger workpieces and perform more complex operations. Another key aspect of future developments is the adjustable features of these machines. With advancements in technology, slotting machines are becoming more customizable, allowing operators to fine-tune various parameters such as cutting speed, feed rate, and tool positioning. These adjustable features not only enhance the precision and efficiency of slotting machines but also make them more user-friendly and adaptable to different machining requirements. As the industry continues to push the boundaries of slotting machine technology, we can expect to see even more innovative and groundbreaking advancements in the years to come.

by Mud@r_M1 | Nov 25, 2023 | Information

Overview

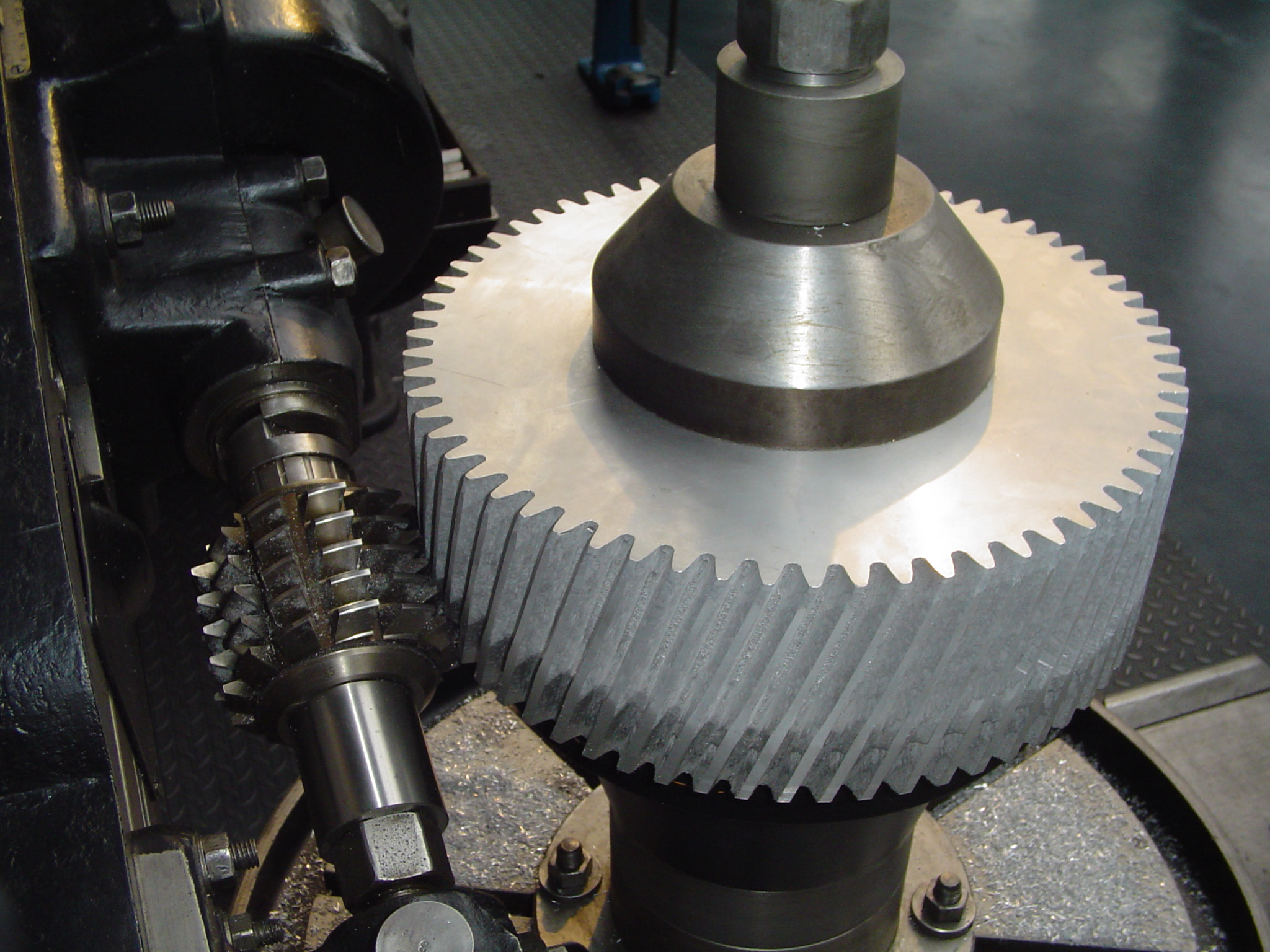

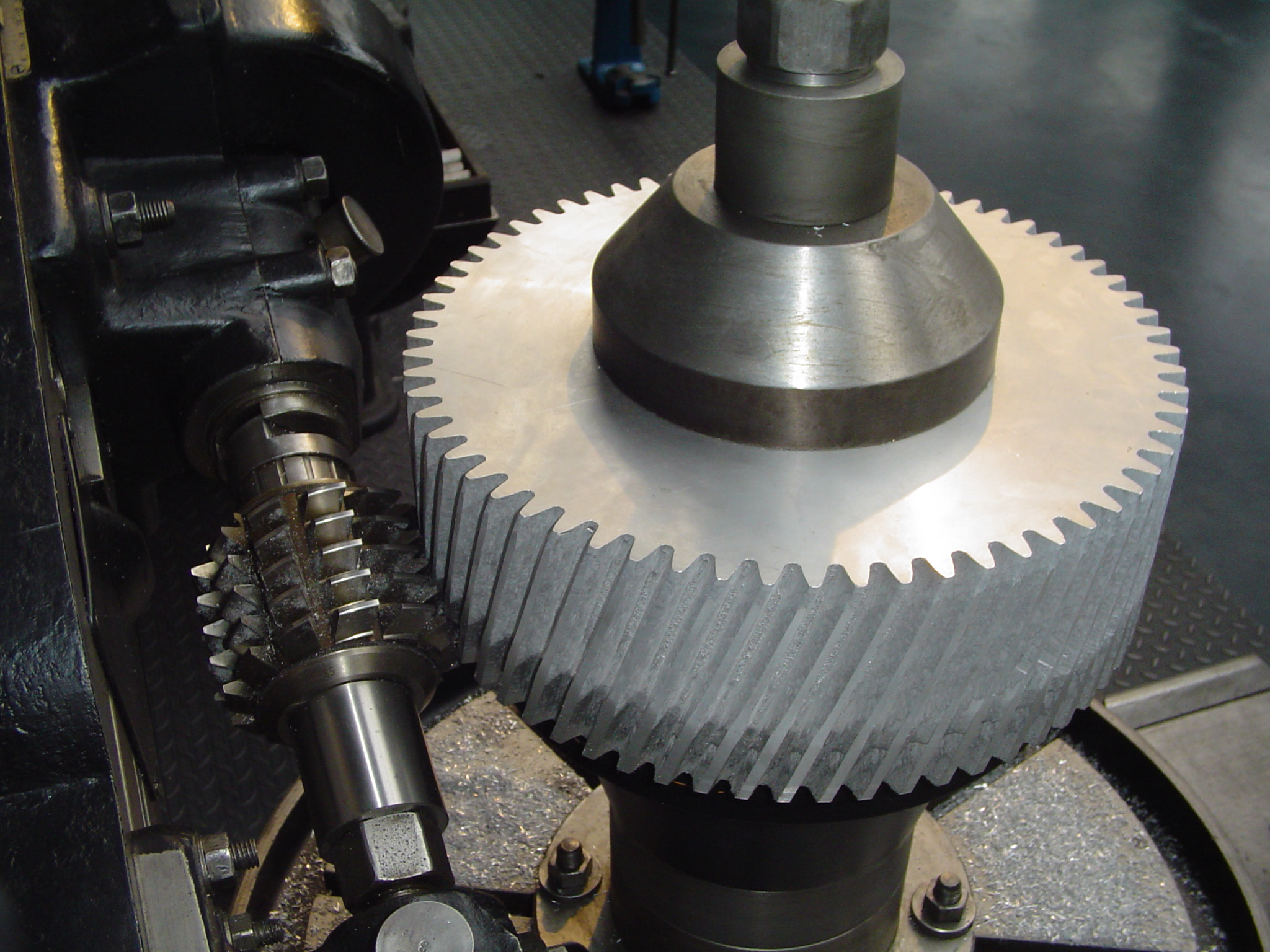

Introduction to gear metalworking machines

Gear metalworking machines are powerful tools used in various industries to manufacture gears. These machines play a crucial role in the production process, as they enable precise cutting, shaping, and finishing of gears. With their advanced features and capabilities, gear metalworking machines have the potential to revolutionize the gear manufacturing industry. In this article, we will explore the various aspects of gear metalworking machines, including their types, applications, and benefits. So, let’s dive into the world of gear metalworking machines and unlock their full potential!

Importance of gear metalworking machines

Gear metalworking machines play a crucial role in the manufacturing industry. They are essential for producing high-quality gears that are used in various applications, such as automotive, aerospace, and machinery. These machines have the ability to cut, shape, and form gears with precision and accuracy. The importance of gear metalworking machines cannot be overstated, as they enable the production of gears that meet the specific requirements of different industries. Without these machines, the manufacturing process would be significantly slower and less efficient. Therefore, investing in advanced gear metalworking machines is essential for companies looking to unlock the full potential of their manufacturing operations.

Types of gear metalworking machines

Gear metalworking machines are an essential tool for manufacturing industries. These machines are designed to produce gears of different sizes and shapes with high precision. There are several types of gear metalworking machines available in the market, each with its own unique features and capabilities. The most common types include gear hobbing machines, gear shaping machines, and gear grinding machines. Gear hobbing machines are used to cut teeth on cylindrical gears, while gear shaping machines are used to shape gears with internal or external teeth. Gear grinding machines, on the other hand, are used to achieve the final precision and surface finish of the gears. With the advancement in technology, gear metalworking machines have become more efficient and versatile, allowing manufacturers to unlock the full potential of gear production.

History of Gear Metalworking Machines

Early developments in gear manufacturing

Gear manufacturing has come a long way since its early developments. In the past, gear manufacturing was a labor-intensive process that required skilled craftsmen to manually shape and cut gears. However, with the advent of gear metalworking machines, the potential for gear manufacturing has been unlocked. These machines have revolutionized the industry by automating the manufacturing process, increasing efficiency, and improving the quality of gears produced. Today, gear metalworking machines are capable of producing gears with precise dimensions and high accuracy. They have become an essential tool in various industries, including automotive, aerospace, and machinery. The early developments in gear manufacturing paved the way for the advancements we see today, making gear metalworking machines an indispensable part of modern manufacturing.

Invention of gear metalworking machines

Gear metalworking machines have revolutionized the manufacturing industry. These machines, which were invented in the early 19th century, have played a crucial role in the production of gears for various applications. With the invention of gear metalworking machines, the process of gear manufacturing became faster, more efficient, and more precise. These machines have enabled manufacturers to create gears with complex designs and tight tolerances, allowing for the production of high-quality products. Today, gear metalworking machines are widely used in industries such as automotive, aerospace, and machinery. They have unlocked the potential for innovation and advancement in the field of gear manufacturing.

Evolution of gear metalworking machines

Gear metalworking machines have come a long way in their evolution. From simple manual machines to sophisticated computer-controlled systems, the advancements in this field have been remarkable. These machines have revolutionized the manufacturing industry by increasing productivity, precision, and efficiency. The introduction of CNC technology has allowed for greater flexibility and accuracy in gear production. Today, gear metalworking machines are capable of producing gears of various sizes and complexities, meeting the demands of diverse industries such as automotive, aerospace, and robotics. With continuous research and development, the potential of gear metalworking machines is constantly being unlocked, pushing the boundaries of what is possible in gear manufacturing.

Advantages of Gear Metalworking Machines

Increased efficiency and productivity

Gear metalworking machines have revolutionized the manufacturing industry, providing increased efficiency and productivity. With advanced technology and precision engineering, these machines are capable of producing high-quality gears with minimal human intervention. The automation features allow for faster production cycles and reduced downtime, resulting in improved overall efficiency. Moreover, the integration of smart sensors and data analytics enables real-time monitoring and predictive maintenance, further enhancing productivity. By unlocking the potential of gear metalworking machines, manufacturers can streamline their operations, meet growing demands, and stay ahead in today’s competitive market.

Precision and accuracy in gear manufacturing

Precision and accuracy are crucial in gear manufacturing. The ability to produce gears with precise dimensions and tight tolerances ensures optimal performance and functionality. Gear metalworking machines play a vital role in achieving this level of precision. These machines are designed to handle the complex processes involved in gear manufacturing, such as cutting, shaping, and finishing. By utilizing advanced technologies and innovative techniques, gear metalworking machines unlock the full potential of gear manufacturing. They enable manufacturers to produce high-quality gears that meet the demanding requirements of various industries, including automotive, aerospace, and robotics. The precision and accuracy offered by gear metalworking machines not only enhance the performance of the gears but also contribute to the overall efficiency and reliability of the machines or systems in which they are used.

Versatility and flexibility in gear production

Gear metalworking machines are revolutionizing the manufacturing industry. With their versatility and flexibility, these machines are unlocking the potential for efficient and precise gear production. Whether it’s creating gears for automotive, aerospace, or industrial applications, gear metalworking machines can handle the task with ease. The ability to produce a wide range of gear sizes and types makes these machines indispensable in today’s fast-paced and ever-changing market. From spur gears to helical gears, from small gears to large gears, gear metalworking machines can handle it all. With their advanced technology and precise engineering, these machines ensure that every gear produced meets the highest quality standards. So, if you’re looking to take your gear production to the next level, look no further than gear metalworking machines.

Applications of Gear Metalworking Machines

Automotive industry

Gear metalworking machines play a crucial role in the automotive industry. These machines are used for a variety of tasks, such as cutting, shaping, and finishing gears. They are essential in the production of automobiles, as they ensure the precise and efficient manufacturing of gears. With the advancements in technology, gear metalworking machines have become more advanced and sophisticated, allowing for greater precision and productivity. Automotive manufacturers rely on these machines to produce high-quality gears that meet the strict standards of the industry. By unlocking the potential of gear metalworking machines, the automotive industry can continue to innovate and improve the performance of vehicles.

Aerospace industry

Gear metalworking machines play a crucial role in the aerospace industry. These machines are designed to efficiently produce gears and other metal components that are used in aircraft and spacecraft. With their advanced technology and precision, gear metalworking machines enable manufacturers to create high-quality and reliable parts for the aerospace industry. Whether it’s for engines, landing gear, or control systems, these machines are essential in meeting the demanding requirements of the aerospace industry. By unlocking the potential of gear metalworking machines, manufacturers can enhance their production capabilities and contribute to the advancement of aerospace technology.

Industrial machinery manufacturing

Gear metalworking machines are an essential part of the industrial machinery manufacturing industry. These machines play a crucial role in the production of gears, which are vital components in various applications such as automotive, aerospace, and machinery. With their advanced technology and precision engineering, gear metalworking machines have the potential to revolutionize the manufacturing process, increasing efficiency and productivity. By unlocking the full potential of these machines, manufacturers can optimize their operations and stay competitive in the global market. Whether it’s cutting, shaping, or finishing gears, gear metalworking machines offer unparalleled accuracy and reliability. With their ability to handle complex designs and high volumes, these machines are a game-changer for the industry. Embracing the power of gear metalworking machines is the key to unlocking new possibilities and achieving greater success in industrial machinery manufacturing.

Latest Innovations in Gear Metalworking Machines

Advanced automation and robotics

Advanced automation and robotics are revolutionizing the field of gear metalworking machines. With the rapid advancement of technology, manufacturers are now able to incorporate cutting-edge automation and robotics systems into their gear metalworking processes. These advanced systems not only enhance productivity and efficiency but also improve the overall quality and precision of the gear manufacturing process. By automating various tasks such as material handling, tooling, and inspection, gear metalworking machines can now operate with minimal human intervention, resulting in faster production cycles and reduced errors. The integration of robotics in gear metalworking machines also allows for greater flexibility and adaptability, enabling manufacturers to easily switch between different gear types and sizes. This advanced automation and robotics technology has unlocked the true potential of gear metalworking machines, making them indispensable tools in the modern manufacturing industry.

Integration of IoT in gear manufacturing

Gear manufacturing has seen significant advancements in recent years, thanks to the integration of Internet of Things (IoT) technology. By connecting gear metalworking machines to the IoT, manufacturers can unlock a new level of efficiency and productivity. IoT integration allows for real-time monitoring and analysis of machine performance, enabling proactive maintenance and reducing downtime. Additionally, IoT-enabled machines can collect and analyze vast amounts of data, providing valuable insights for process optimization and quality control. With the integration of IoT in gear manufacturing, manufacturers can revolutionize their operations and stay ahead in today’s competitive market.

Enhanced software and control systems

Enhanced software and control systems have revolutionized the world of gear metalworking machines. With cutting-edge algorithms and intuitive interfaces, these advancements have made operating and programming gear machines easier and more efficient than ever before. The enhanced software allows for seamless integration with other manufacturing systems, enabling a higher level of automation and precision. Additionally, the control systems have been enhanced to provide real-time monitoring and diagnostics, ensuring optimal performance and minimizing downtime. This combination of advanced software and control systems unlocks the full potential of gear metalworking machines, making them indispensable tools for modern manufacturing.

Conclusion

Unlocking the full potential of gear metalworking machines

Gear metalworking machines are a crucial component in the manufacturing industry, enabling the production of precise and high-quality gears. These machines are designed to unlock the full potential of gear manufacturing, providing increased efficiency, accuracy, and productivity. By utilizing advanced technologies and innovative features, gear metalworking machines offer unparalleled performance and versatility. From gear hobbing to gear shaping, these machines can handle a wide range of gear manufacturing processes, catering to the diverse needs of various industries. With their ability to deliver exceptional results, gear metalworking machines are indispensable tools for manufacturers looking to stay ahead in today’s competitive market.

Future prospects of gear metalworking machines

Gear metalworking machines have come a long way in terms of technological advancements and performance. With the continuous development of automation and artificial intelligence, the future prospects of gear metalworking machines are incredibly promising. These machines are expected to become even more efficient, accurate, and versatile, allowing manufacturers to achieve higher productivity and quality in their operations. The integration of smart technologies will enable real-time monitoring and analysis, leading to proactive maintenance and reduced downtime. Additionally, gear metalworking machines will likely incorporate advanced features such as predictive maintenance, self-adjustment capabilities, and seamless integration with other smart manufacturing systems. This will not only enhance the overall performance and reliability of these machines but also contribute to the optimization of the entire production process. As the demand for precision gears continues to rise in various industries, gear metalworking machines will play a crucial role in meeting these requirements and unlocking new possibilities in the manufacturing sector.

Continued advancements in gear manufacturing technology

Gear manufacturing technology has come a long way over the years, with continued advancements pushing the boundaries of what is possible. Today, gear metalworking machines are unlocking new levels of potential, allowing for more precise and efficient production. These machines utilize cutting-edge technology to create gears with incredible accuracy and durability. The combination of innovative design and state-of-the-art manufacturing processes has revolutionized the gear manufacturing industry. With each new development, gear metalworking machines are becoming more versatile, reliable, and capable of meeting the demands of modern applications. As the industry continues to evolve, we can expect even more exciting advancements in gear manufacturing technology.